228号楼构成DTU化工学院——配有高国际标准设施的世界一流研究与创新教学楼。大楼内设有实验室、教室、工坊设施以及叫做“PILOT PLANT”的大型实验室,此外还设有公共学生设施以及行政区域。 Mikkelsen事务所的项目包括新建和改造,以及满足DTU对教学和研究空间的需求。DTU表示希望创造开放、灵活的工作环境,以激励员工和学生,并确保更高效、实践的研究环境和操作过程。DTU还希望该项目能够提升DTU化工学院作为领先化学与生物工程领域的大学院系之一的地位,并彰显DTU对实用和可行研究、教育与创新的关注。

Building 228 forms the framework of DTU Chemical Engineering – a building for world-class research, innovation and teaching, with facilities of the highest international standard. The building houses laboratories, classrooms, workshop facilities and a large-scale experimental facility, called PILOT PLANT. The building also houses common student facilities, as well as administrative areas. Mikkelsen’s project entailed new construction and renovation and addressed DTU’s need for teaching and research space. The client, DTU, expressed the desire to create open, flexible work environments that would inspire employees and students, and ensure more efficient, hands-on research environments and work processes. The client wanted the project to promote DTU Chemical Engineering’s position as one of the leading university institutes in the Chemical and Biochemical Engineering field in the world, and emphasize DTU’s focus on practical and viable research, education and innovation.

▼从停车场望向建筑,view to the building from the parking area © Hampus Berndtson

Mikkelsen Arkitekter事务所设计了228号楼,以适应未来的学习和创新环境。除了创造更好的新设施外,228号楼还将现有建筑连接在一起,在研究、教学和知识共享之间创造更好的流通与协同,在这里,学生可以将理论转化为实践,也可以进行大规模实验。研究设施的设计具有高度灵活性,因此可以根据未来需求轻松地进行改造。Mikkelsen Arkitekter事务所优化了使用过程,并确保该项目满足特殊学习环境的要求。通过培养学生在半工业规模空间中进行操作,将基础研究从实验室转移至工业用途。实验设施和实验室能够进行生物质、生物燃料、发酵、制药生产、粒子技术、有机溶剂、高温实验和气化实验。

Mikkelsen Arkitekter designed Building 228 to accommodate the learning and innovation environments of the future. In addition to creating new and better facilities, 228 also links the existing buildings together, creating better flow and synergy between research, teaching and knowledge sharing, where one can translate theory into practice, also with large-scale experiments. The research facilities are designed with a high degree of flexibility, so they can be easily transformed according to future requirements. Mikkelsen Arkitekter facilitated the user process and assured that the project met the special learning environment requirements, in the way of training and educating students to work on a semi-industrial scale, and be able to transfer fundamental research from the laboratory to industrial use. The experimental facilities and laboratories are designed and equipped to be able to work with biomasses, biofuels, fermentation, pharmaceutical production, particle technology, organic solvents, high-temperature experiments and gasification experiments.

▼从庭院望向建筑,view to the building from the courtyard © Hampus Berndtson

DTU改造为了满足高标准要求,内部必须设有多功能教学区和配备大量专业设备的实验室。在该项目中,Mikkelsen事务所的目标是为未来研究环境开发长期、可持续的解决方案,促进学生、研究人员、员工和访客之间的互动,同时确保布局和多用途方面的灵活性。设计团队进行了以价值为基础的优化,使楼内空间提升了学生活动的标准,例如促进更具创造性和协同性的环境。设计团队还进行了定量优化,使空间得到更好的利用,例如空间的多样化使用。

To transform DTU’s building according to high architectural requirements, the new rooms had to be multi-functional teaching zones and laboratories with extensive technical installations. With 228, it was Mikkelsen’s goal to develop long-term, sustainable solutions for future research environments, supported by a design that strengthens the interaction between students, researchers, employees and guests, while assuring flexibility with regards to layout and multiuse. We worked with value-based optimization so that the spaces in Building 228 elevate the standard of DTU’s student activities, for example with regards to promoting a more creative and synergic environment. We also worked with quantitative optimization, so space is utilised more optimally, for example, diversified use of the spaces.

▼建筑之间相互连接,the buildings are interconnected © Hampus Berndtson

在228号楼的设计中,Mikkelsen Arkitekter通过在实体建筑中间创造大量宽敞的功能性连接,为增强学院联系、协同和交流做出了贡献。设计团队确定了整体概念,将建筑划分为实验室、大厅等高技术区域,以及行政、会议室和休息室等低技术区域。通风井使高技术区域直接与屋顶相连,天窗将低技术区域隔开,为室内带来阳光并与使之交通空间保持一致。228号楼与既有的227号和229号楼相连,所有楼层均设有简洁的玻璃隔断和连廊。

With the design of 228, Mikkelsen Arkitekter has contributed to creating connections, synergy and communication, by providing strong, spacious and functional coherence in the actual building. We defined the overall concept, by dividing the building up into the more technical area, with laboratories, halls etc. and the less technical area, with administration, conference rooms and lounge. The technical area is directly connected to the roof via shafts, and the less technical area is separated by skylights that bring sunlight into the building and forms coherence with the circulation space. Building 228 is connected to the existing buildings, 227 and 229 with elegant glass partitions and corridor connections on all floors.

▼玻璃连廊,the glass corridor © Hampus Berndtson

▼格栅遮阳,grille shading © Hampus Berndtson

▼入口,entrance © Hampus Berndtson

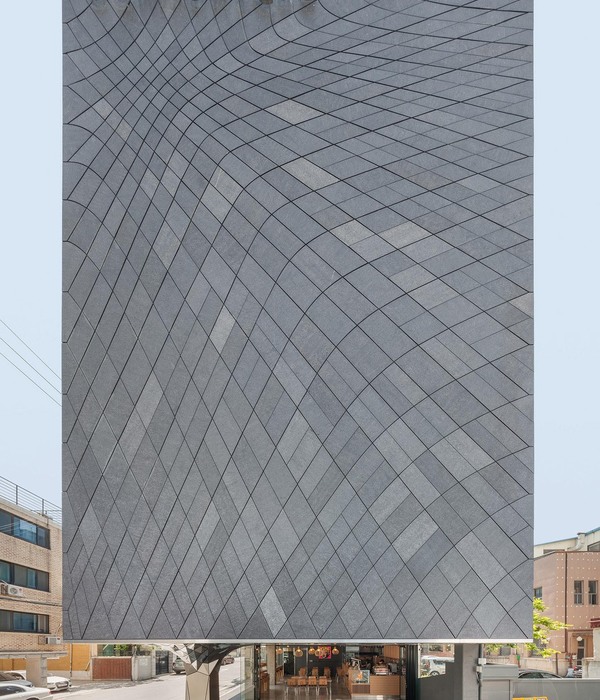

▼外表皮细部,details of the skin © Hampus Berndtson

228号楼采用的可持续方法基于DGNB认证体系,建筑建成后获得DGNB金级认证。 228号楼的设计全面关注经济和环境的可持续性,能耗降至最低,室内气候良好,具有最佳声学和光照环境,并且需要最少的维护。在初始阶段,设计团队基于DGNB体系制定了目标和可持续性战略,并进行了初步筛选。他们以寻找跨学科的解决方案为出发点,从整体经济的角度确保建筑具有最优性能,并在总体设计过程中提出多种对比概念,将重点放在经济和环境方面,例如优先考虑可持续性主题。 Mikkelsen事务所推动了独立可持续工坊的发展,并参与了与建筑可持续发展相关的决策过程。

The sustainability methodology used in Building 228 was based on the certification system DGNB, and the completed building can be classified as DGNB Gold. Building 228 has been designed with a comprehensive focus on economic and environmental sustainability and has minimal energy consumption, a good indoor climate, has optimal conditions in terms of acoustics and daylight, and requires minimum maintenance. In the initial phase, the design team developed an objective and a sustainability strategy, based on DGNB and carried out an initial screening. The point of departure was to find interdisciplinary solutions, which could ensure that the building was optimal, from an overall economic perspective, and various comparative concepts were developed in the integrated design process, with focus on the economic and environmental aspects, including a prioritization of sustainability topics. Mikkelsen facilitated separate sustainability workshops and was a part of the decision-making process in relation to the building’s sustainability status.

▼低技术区,the less technical area © Hampus Berndtson

▼高技术区,the more technical area © Hampus Berndtson

▼轴测分解图,exploded axon © Mikkelsen Architects

▼总平面图,site plan © Mikkelsen Architects

▼一层平面图,ground floor plan © Mikkelsen Architects

▼二层平面图,first floor plan © Mikkelsen Architects

▼三层平面图,second floor plan © Mikkelsen Architects

▼立面图,elevation © Mikkelsen Architects

▼剖面图,section © Mikkelsen Architects

▼构造节点,details © Mikkelsen Architects

Project size: 6342 m2 Project team: Mikkelsen Architects, MOE, LINK Architects

{{item.text_origin}}