哈威是巴伐利亚一家生产移动液压系统及配件的公司,它于2008年举办了一场设计竞赛,旨在巴伐利亚边缘的阿尔高和阿尔卑斯山农区建造一座生产中心,Barkow Leibinger建筑事务所在这场竞赛中胜出。尽管项目中途受到全球经济危机的影响而停顿,但在简化方案后,这一面积高达50 000平方米的项目如期于2014年竣工。

HAWE, a manufacturer in Bavaria of mobile hydraulic systems and components, initiated a design competition in 2008, won by Barkow Leibinger, for a new production center in the context of an agricultural landscape at the edge of the Bavarian Allgäu and Alps. After a postponement due to the international economic crisis of the intervening period, the 50 000 square meters project was simplified, developed and completed on-time / under-budget in 2014.

▼建筑外观,external view

这家绿色工厂的整体造型如同一个玩具风车,中心为一个由办公室,会议室和咖啡厅围合而成的庭院,四座生产车间就像风车的叶片,围绕中心旋转排布。从咖啡厅可以看到南部和阿尔卑斯山的景观。

Conceived as a “green factory”the plan is organized around a pin-wheel of four building volumes of production halls which rotate around a central courtyard surrounded by offices, conference rooms, and cafeteria with views to the south and Alps.

▼ 办公室,会议室和咖啡厅围合而成的庭院,a central courtyard surrounded by offices, conference rooms, and cafeteria

风车式的建筑平面让工人也可享受到一些景色,同时使建筑的尺度和周边环境相协调。不同于公司其他的工厂,建筑不是单调的“大盒子”形状,凸出的小屋顶模仿周边山峰和村庄的形状,使由金属板,玻璃和半透明槽形玻璃组成的立面剪影更为生动。

The pinwheel organization offers offset views for the workers into the landscape and help scale the large building down in the context of the landscape. The shed roofs mimic the nearby alpine topography of peaks and valleys and animate the buildings silhouette a geometry that extends down the facades as articulated in sheet metal, glass, and translucent channel-glass, an approach avoiding the monotony of typical “big-box” typologies that proliferate near much of our industrial areas and roadways.

集成机器系统减小了占地,在网格结构下平面布局更加自由。屋顶天窗朝北设置,使得室内可以有均匀的采光;日照强烈的南侧表面选用遮光隔热材料,且安装光电板以利用太阳能。为了提高生产速度并且节约成本,工厂的跨度梁和屋顶使用的三明治板均为预制产品。

The integration of mechanical systems and the grid-like structural system allowed for flexible floor layouts. The roof sheds are oriented to the north, classically, offering even daylighting while the opaque surfaces of the sheds orient to the south, ideally, for photovoltaic panels. In order to increase speed of construction and to reduce costs the wide span beams of the halls and the sandwich elements of sheet metal for the roofing were prefabricated.

▼ 工厂内部,Factory

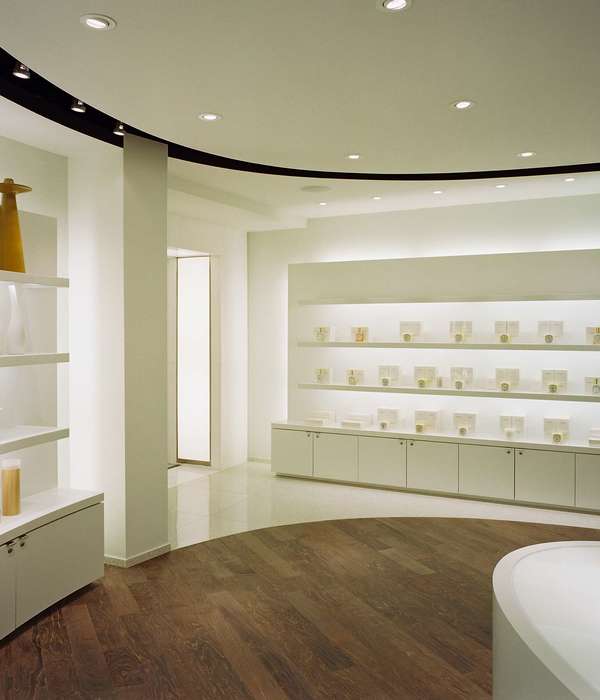

▼餐厅,Cafeteria

▼入口和楼梯,Entrance and Staircase

工厂采用多点同时施工的方式建造,节约工期的同时保证了建筑的质量,使这里的生产流程得到了优化。

The factory is exemplified here by a flexible and a serial construction system that enhances the workspace and improves the processes for the things that are made there.

▼ 分析图, Diagram

▼ 总平面。Site Plan

▼平面图,Floor Plans

▼剖面图,Sections

▼ 建筑细节,Detail Drawing

Project Information

Architects — Barkow Leibinger, Berlin, Frank Barkow, Regine Leibinger

Team Design — Martina Bauer (Project Architect), Natascha Bauer, Frederic Beaupere, Aki Nagasaka, Ruwen Rimpau, Morihide Seki, Jens Wessel

Team Construction — Lukas Weder (Project Architect), Matthias Anke, Franz Brunnert, Ulrich Fuchs, Johannes Gestering, Michael Johl, Henrike Kortemeyer, Arne Löper, Mathias Oliva Y Hausmann, Andrea Hronjec, Ruwen Rimpau, Morihide Seki, Antje Steckhan, Jonas Troescher, Tim Unnebrink

Program-Production and Assembly Halls, Offices, Conference Room, Canteen, Kitchen, Storage

Location-Kaufbeuren, Germany

Size-50.039 sqm

Construction-2012 – 2014

Client-HAWE Hydraulik SE

Project Management-Ingenics AG, Ulm

Construction Management-Höhler + Partner, Aachen

Structural Engineer-Dobler GmbH & Co. KG Planungsbüro, Kaufbeuren

HVAC and Plumbing-Albrecht GmbH, Kammlach

Electrical Engineer-Christian Kaindl, Nandlstadt

Energy Design-Rögelein + Partner Ingenieure GbR, Munich

Façade Consultant-Priedemann Fassadenberatung GmbH, Berlin

Building Physics-Müller-BBM GmbH, Planegg

Landscape Architect-Stefanie Jühling, Munich

{{item.text_origin}}