- 项目名称:维他奶东莞食品饮料生产中心

- 设计方:ZZT工业建筑

- 摄影版权:合作方:广州轻工院

- 客户:维他奶国际集团

维他奶,作为香港电影里的标志性代表,现如今越来越多出现在我们的生活场景中。仲夏夜,约上三五好友撸串、聊天,大汗淋漓之际喝上一口冰爽、顺滑的维他奶,可谓是非(fei) 常(soeng)过(gwo) 瘾(jan)。口感醇厚的豆香造就了它的非凡味道,大量的蛋白质和碳水化合物充分补充了我们每位食客们的营养需求。在与好友欢聚之余,有了这一份承载着丰富情感的饮品加入,不禁让人沉浸其中。

而远在广东东莞的维他奶工厂,工人们以最有序最高效的方式,与北纬45°中国黄金种植区的天然大豆/优质的原材料产生交流。尖端的生产设备、合理的空间规划、良好的作业体验… …在这座专业且现代化的工厂内,设计不在于它长什么样子,而在于它以何种方式运作。

▼建筑远景,distanced view of the building ©schranimage

Vitasoy, as a key sign appeared in the Hong Kong movies, is now more and more appearing in our life. It would be extremely enjoyable to take a mouthful of cold but smooth Vitasoy while having a good time to chat and eat spicy food with good friends on a midsummer night. The full-bodied bean flavor creates its extraordinary taste, and a large amount of protein and carbohydrate fully supplement the nutritional needs of us. The strong emotional attach in this drink makes us immerse ourselves in our time with friends.

At the Vitasoy factory in Dongguan, Guangdong Province, the workers work in the most orderly and efficient way on the high-quality raw materials/ natural soybean which grows in gold planting area of China at 45 n°. Sophisticated production equipment, reasonable space planning, good working experience… In this professional and modern factory, the design is not about what it looks like, but how it operates.

▼项目鸟瞰,aerial view of the project ©schranimage

自设计之初到现在,维他奶东莞食品饮料生产中心的诞生过程历时4年。我们在遵循工业建筑尺度感的同时,还将实用性、经济性和流线组织作为设计的关键驱动因素。

It takes four years for the Vitasoy factory from the initial design to the completion. While following the sense of scale of industrial buildings, we also take practicability, economy and streamline organization as the key driving factors of design.

▼生产功能分析,function analysis of the production workshop ©ZZT工业建筑

维他奶从原材料入库到最终变成大家口中的美味饮品,材料(包括原辅材料、包装材料和成品材料三大类)是生产的重要元素。因此,物流及仓储区的空间规划是一个摆在我们面前的大难题。如果物流、仓储与生产车间的关系处理不好,很可能造成总体布局紊乱,流程交叉或颠倒,材料进出库不流畅等问题,长此以往将直接影响工厂运营效率。

During the production process before taking by the public as a delicious beverage, the materials (including raw and auxiliary materials, packaging materials and finished products) is the key element of production. Therefore, the spatial planning of logistics and storage area is a big problem in front of us. If the arrangement and management on the logistics, storage and production workshop can not be handled and related well, it is likely to cause problems such as overall layout disorder, process crossing or reversal, poor material storage management, which will directly affect the operation efficiency of the factory in the long run.

▼开阔的室外空间保证交通顺畅,large outdoor spaces ensuring the fluency of the circulation ©schranimage

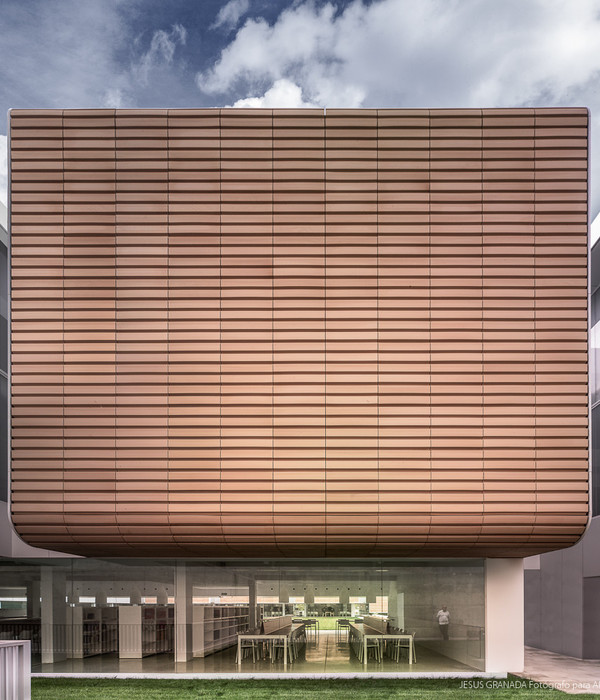

▼工厂立面,facade of the factory ©schranimage

▼立面细部,details of the facade ©schranimage

除了考虑工艺需求外,我们还注重工厂的使用体验。维他奶东莞工厂占地约150亩,能够同时满足生产、办公及员工宿舍等基本功能。这样“三件套”的功能配置,在东莞的工厂中不算特别,但区别于其他工厂只为生产的糟糕环境,我们在设计时将厂前区、生活区、生产区通过周界系统实现分区管理、增强体验度,让真正的打工人有质量的工作与生活。

▼功能分区,function analysis ©ZZT工业建筑

In addition to considering the process requirements, we also pay attention to the use experience of the factory. Vitasoy Dongguan factory covers an area of about 100,000 square meter, which can meet the basic functions of production, office and staff dormitory at the same time. This “three sets” function configuration is not special in those Dongguan factories, but it is different because while other factories only focus on production, Vitasoy factory is designed to use the perimeter system to realize the partition management of the factory front area, the living area and the production area, so as to enhance the experience which the workers and employees can work and live in high quality here.

▼不同功能的建筑体块,architectural volumes with different functions ©schranimage

维他奶工厂物流进、出库比例约为1:10。看似简单的数字背后,需要环环相扣的设计才能支撑起内部复杂的物流系统有序运行。通常,原材料入库车辆约为20辆/日,成品出库车辆约为100-200辆/日,高峰期出货车流约为300- 400辆/日。针对昼夜不停的物流需求,我们既要考虑人员与车辆的安全问题,也要照顾到他们的心里需求。预留货车等候区、确保运送原材料的车辆不经厂区内其他区域,不需要倒车掉头,高效离场。物流区在空间、照明、指示系统等多方面综合考虑。15米无柱式悬挑结构,空间干净、视线通透,确保AGV叉车、大型货车倒车安全;雨棚下方的照明设计,让夜间作业有了安全保障;专门预留的等候室,为长途司机提供了休憩空间。

▼流线分析,circulation analysis ©ZZT工业建筑

The import and export ratio of Vitasoy factory is about 1:10. Behind this numbers, there is a interlocking design supporting the orderly operation of the internal complex logistics system. Generally, the number of trucks entering the warehouse for raw materials is about 20 vehicles / day, the number of trucks leaving the warehouse for finished products is about 100-200 vehicles / day, and the number of trucks leaving the warehouse during the peak period is about 300-400 vehicles / day. In view of the day and night logistics demand, we consider not only the safety of personnel and vehicles, but also their psychological needs.

▼宽敞的装卸区,large loading area ©schranimage

员工及相关劳动者是生产活动的主体,也是工业建筑中使用频率最高的使用者。Z世代的打工人不仅要实现自我价值,还要更有尊严的工作。我们通过系统的周界设计,将生活区与工作区有效隔离、刷卡管理。这不只是为了员工的安全考虑,还从心理层面尊重他们对仪式感的需求,平衡工作与生活的关系。

▼管理设施和流线分析,administration facilities and circulation analysis ©ZZT工业建筑

Employees and related workers are the main part of production activities, and they are also the most frequently used users in the industrial buildings. Z generation workers should not only realize their self-worth, but also work with dignity. Through systemic perimeter design, we can effectively isolate the living area from the work area and manage it by swiping the card. This is not only for the safety of employees, but also to respect their needs for ritual sense from the psychological level and balance the relationship between work and life.

▼生活区外观,external view of the living area ©schranimage

宿舍底层半开放空间将园区中的各种共享功能置入其中。我们通过架空、遮阳的设计,使户外公共活动空间更好适应东莞当地气候。闲暇的时候约上好友,看看书,健健身,一起放松、一起娱乐,打工的生活也变得不那么枯燥了。

The semi open space on the bottom floor of the dormitory places contains various sharing functions of the park. Through the design of overhead and sunshade, we make the outdoor public space better adapt to the local climate of Dongguan. It becomes a good place to spend leisure time with friends to read books, fitness, relax and have fun together, which make the working life less boring.

▼架空廊道和草坪,elevated corridors and lawns ©schranimage

▼室外走廊,outdoor corridor ©ZZT工业建筑

▼室内公共空间,interior public space ©schranimage

参观流线是现代工厂展现企业文化的极佳通道。有别于其他企业展厅与车间地面参观的传统模式,我们从纵向空间切入设计,双层、架空的参观通道贯穿生产区及高架库两个核心区域。参观者透过15°斜面的玻璃廊道,可以更清晰、直观的观赏车间生产情况。垂直空间的利用,避免参观者与员工流线重合进而影响生产秩序。

▼参观流线分析,visiting streamline analysis ©ZZT工业建筑

Visiting streamline is an excellent channel for modern factories to show the company culture. Different from traditional visiting mode of other companies which visit the exhibition hall and workshop ground, we design the visiting via cutting the longitudinal space, the double-layer and overhead visiting passage runs through the two core areas —- the production area and the elevated warehouse. The 15°inclined glass corridor provide the visitors a clearer and more intuitive view of the production situation of the workshop. The use of vertical space can avoid the overlap of the visitors and staff streamline so as to avoid affecting production process.

▼参观通道,visiting passage ©schranimage

▼生产空间,workshop ©schranimage

园区内部运营管理秩序展现着企业的状态和价值。我们借助空间规划,塑造了清晰的物流系统、人行系统、车行系统和运维系统,这些繁杂且清晰的流线,映衬出内部管理的逻辑,也构成了维他奶“大物流”工厂的基础。可以说,工业建筑蕴含的所有隐性秩序,在维他奶项目中都得到淋漓尽致的体现。

The internal operation and management order of the park shows the status and value of the company. With the help of space planning, we have created a clear logistics system, pedestrian system, vehicle system and operation and maintenance system. These complex and clear streamlines reflect the logic of internal management and form the basis of Vitasoy’s “big logistics” factory. It can be said that all the hidden order contained in the industrial building is fully reflected in the Vitasoy project.

▼夜景,night view ©schranimage

▼总平面图,site plan ©ZZT工业建筑

▼工厂立面图,elevation of the factory ©ZZT工业建筑

{{item.text_origin}}