悉尼乔治街 200 号 | 参数化设计引领高层建筑新纪元

Mirvac 和 FJMT Studio 最近在乔治街200号设计的大厦,标志着澳大利亚高层建筑的新纪元已经到来。建筑使用木材搭配玻璃作为立面,设计师希望将可持续设计与商业建筑相结合,为悉尼带来全新的环境和美学标准。Mirvac集团邀请AR-MA公司为建筑做立面设计。这个团队还包括主持结构设计的ARUP公司,以及负责立面建造和装配的 Empire Glass和Aluminium公司。与这些团队合作,AR-MA公司能更高效完成建筑立面设计。

Mirvac and FJMT Studio’s recent tower at 200 George Street heralds a new era in high rise building design, particularly in an Australian context. Employing a novel timber-and-glass façade system, the building seeks to better integrate sustainable design within commercial architecture, providing Sydney with a new aesthetic and environmental standard. AR-MA was engaged by Mirvac as part of a specialist façade team to manage design and construction of the podium glazing and cladding. This team also included ARUP, who managed structural engineering, and Empire Glass and Aluminium, who managed fabrication and installation. Working within this team, AR-MA was able to efficiently rationalise the design intent of the architect into an efficient and buildable system incorporating the latest in design technologies.

▼建筑外貌,surface

项目将参数化模型用于所有建造过程。AR-MA公司利用参数化模型,大规模定制装配模件,用独特的方式打造出令设计师满意的立面效果。AR-MA公司直接与装配制造商一同进行生产工作,省去了传统的现场勘查和场地调配过程。这些工厂生产的安装包有着现场制造无法满足的精度。为了省去现场装配人员查阅图纸说明,每一个出厂部件都整合发配,并插入独立标签。

Throughout the project, AR-MA maintained parametric design and fabrication models for all areas of their scope. This allowed AR-MA to move the design outside of conventional building methods and proprietary products, and enable massive customization to produce a highly specific, intentional, and bespoke architecture, satisfying the architect’s intent and the realities of building. Rather than producing traditional drawing packages to outline construction and site installation, AR-MA worked directly with fabrication subcontractors in order to produce direct-to-fabrication, for-manufacture packages. These packages were used to produce highly complex building components within tight tolerances, in a manner not possible on site. To further reduce the number of drawings required, installation instructions were integrated within these factory-fabricated by milling labels and set-out lines into the components in the factory.

▼装配过程,construction

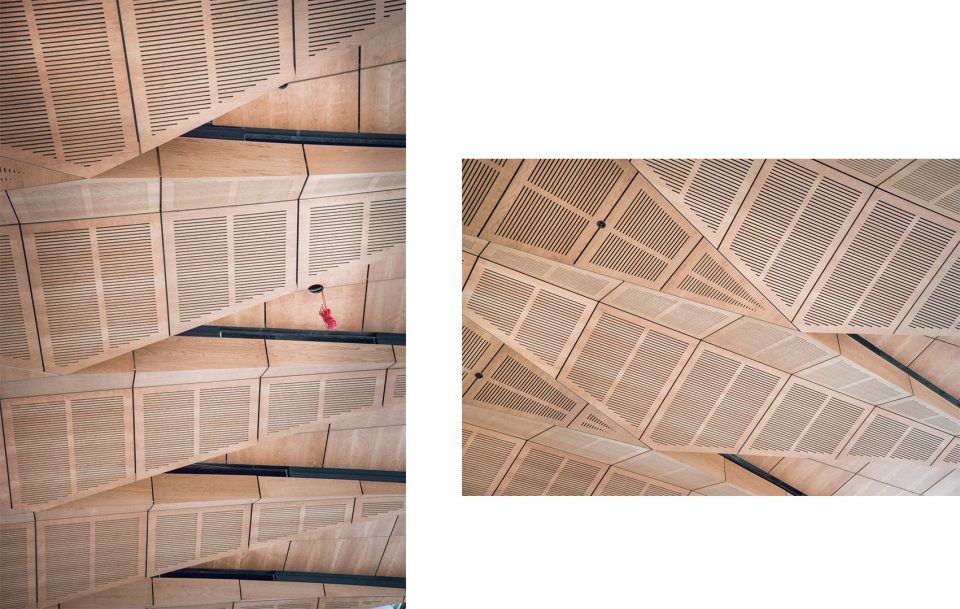

这种灵活的装配方式使得AR-MA公司复杂的几何设计在各个地方得以实现,并能快速回应现场装配的种种问题。设计中包含550多个塑型面板,无框玻璃,CNC线路板,胶合板以及澳大利亚南洋杉木板等,均由AR-MA公司专为这栋建筑量身定制。AR-MA公司以其专业的技术实现了Mirvac 和FJMT Studio在高层建筑建造的更高要求,使这栋位于乔治街200号的大厦成为悉尼当代高层建筑的新标准。

This agile manner of working allowed AR-MA to achieve high levels of geometric complexity in all areas of design, and quickly respond to any issues encountered on site. Over 550 panels of shaped, frameless glass and 1954 5-axis CNC-routed timber panels, fabricated in either glulam or Australian hoop pine plywood were designed by AR-MA for the building. AR-MA’s consultancy allowed Mirvac and FJMT Studio to realise their highly ambitious and sustainable tower at 200 George Street, providing Sydney with a new standard in contemporary high rise design.

▼细节效果,detail

Location: Sydney, Australia

Address: 200 George Street

Year: Feb 15 – Aug 16

Area: 2310 sqm

Collaborators:

Architect: FJMT Studio

Developer: Mirvac

Woozd Fabrication: GDK Group

Glass Fabrication: Empire Glass and Aluminium

Photo Credits: Brett Boardman – AR-MA

MORE:

Francis-Jones Morehen Thorp

,更多关于他们:

.