艾默生过程管理公司办公室转型记

- 项目名称:艾默生过程管理公司办公室转型记

- 设计方:HGA

- 设计团队:Dan Peterson,Matt Dunbar,Dave Kippen,AIA,Chris Willette,Dana Hlebichuk

- 摄影师:Don Wong

America Emerson Process Management

设计方:HGA

位置:美国

分类:办公建筑

内容:实景照片

建筑设计负责人:Chuck Cappellin, PE, LEED AP

机电工程

师:Mark Johnson,Leigh Harrison, PE, LEED AP BD+C

设计团队:Dan Peterson; Matt Dunbar; Dave Kippen, AIA; Chris Willette; Dana Hlebichuk

图片:24张

摄影师:Don Wong

这是由HGA设计的艾默生过程管理公司(EPM),是一个全球领先的高科技测量设备的设计及制造公司。该建筑的设计将优先考虑和服务其制造过程。设计工程师和相关支持部门办公室一直与制造项目息息相关。为了更好地吸引人才,改善目前的公司办公室设计,该公司决定对办公室进行改造。“转型”成为了该项目的设计构思,贯彻到项目的各个方面。设计中没有在现状设施中增加面积,而是对所有非制造区的室内进行改造,以及对建筑外部围合结构进行重建。该项目的目标是为年轻一代提供更为开放的工作场所,加强内部协作,为访客或客户提供更好的沟通和体验,加强建筑的热性能和节能系统。

译者: 艾比

From the architect. Emerson Process Management (EPM) is a global leader in the design and manufacturing of high-tech measurement devices. Emerson products measure and regulate temperature, pressure, and flow rates in liquids, solids, and gas for a variety of industries including: energy, food and beverage, life sciences, and aerospace. Much of the information describing atmospheric conditions on the moon and surface of Mars are measured and transmitted by Emerson devices.

While invention and entrepreneurship has propelled EPM’s success since its formation in 1956, the company’s buildings have been designed to prioritize and solely serve its manufacturing processes. Design engineers and supporting corporate offices have traditionally been co-located with manufacturing programs in facilities designed for production and assembly.

The EPM Eden Prairie Renovation project emerged as a direct response to a growing challenge for the company. Emerson must attract the best engineering talent in the industry to support the complexity of design and material science inherent in its product development. Given current innovations in the design of corporate office workplace and changing generational demographics, EPM’s dated office facilities compromise the company’s efforts to attract and retain the best talent.

“Transformation” became the singular design vision that informed each aspect of the project. Without adding a single square foot to the existing facility, the reconstruction of the exterior envelope and renovation of all non-manufacturing interior programs, Emerson’s goal was to transform its Eden Prairie, Minnesota facility to meet a younger generation’s expectations for open workplace, enhancing collaboration within the engineering groups, and to better communicate the Emerson brand as part of the visitor/customer experience, and to enhance the thermal performance and energy efficiency of building systems.

Emerson Process Management is housed in three combined manufacturing/office buildings in the southwest suburbs of Minneapolis, Minnesota. The existing Eden Prairie facility is an aggregation of multiple building additions constructed between the years 1964 to 1991. Designed to dimensions ideal for large manufacturing floor plates, the main volume of the building is a two-story 300’ x 400’ rectangle set into sloping grade. The full height two-story volume is expressed on the east elevation while only the upper level is visible to the west.

The rural farmland context for the original 1964 building has transformed over the past five decades into a ubiquitous suburban context of big-box retail and light manufacturing. Other than a sloping lawn with mature ash, maple, and oak trees to the north, the EPM property is maximized with building footprint and much needed parking. Given these site challenges, the design team sought to identify and enhance the few site opportunities serving the goal of building transformation: (1) views looking east over Lake Idlewild, (2) views looking to the north sloping lawn and legacy trees, (3) building proximity and visibility to State Hwy 212/5, (4) localized/intimate landscape areas adjacent to primary entries, and (5) comparable building scale and presence relative to big-box neighbors.

Each of these opportunities were positively exploited to provide views from interior office workspaces, reflect and expand the presence of landscape in the curtain wall glass, provide a highly visible beacon expressing the Emerson brand along a highly trafficked highway, and sponsor an architectural dialogue between the newly renovated and transparent “big-box” and its utilitarian neighbors.

The program and design goals for the project were defined in a feasibility study that preceded building design. Having chosen renovation instead of new construction, Emerson was committed to a comprehensive building transformation inside and out. Design goals for the exterior focused on increased daylight, enhancing energy performance, and incorporating brand awareness and on a highly visible site.

Emerson is a fiscally conservative organization and, while being committed to transforming the Eden Prairie facility, corporate leadership would fund only those design proposals that were deeply rooted and pragmatic goals. Respectful of this value-driven goal, the design team sought poetic expression through rigorous structural logic, finely machined repetitive elements, refined detailing, and abundant natural light and view.

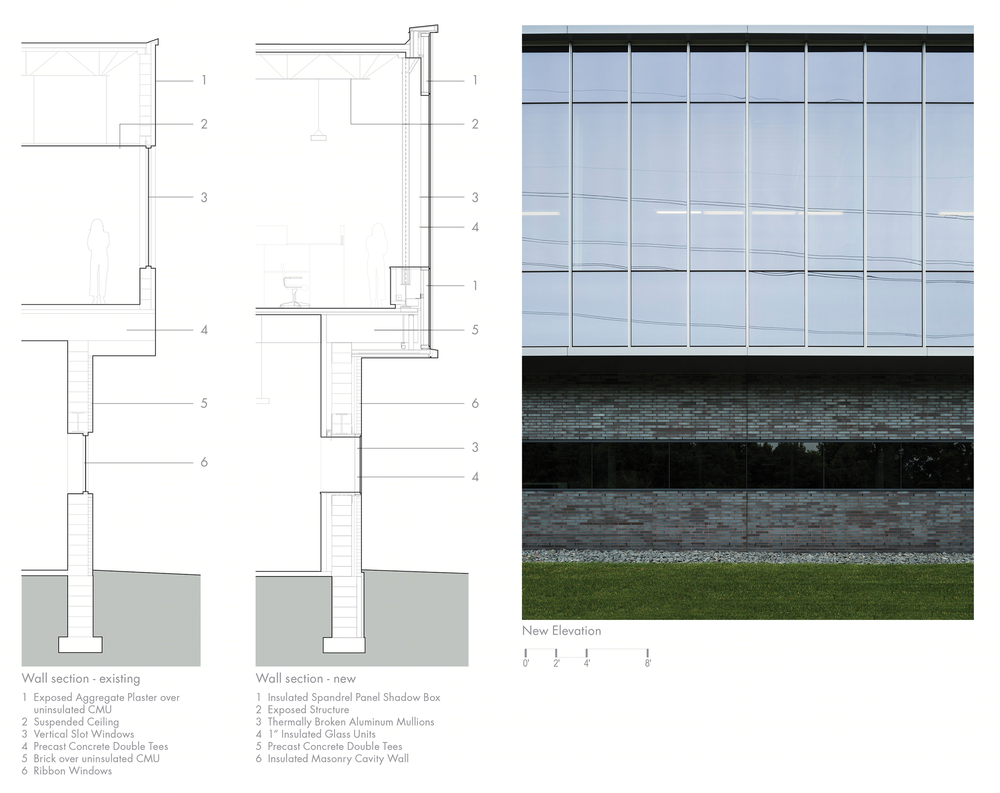

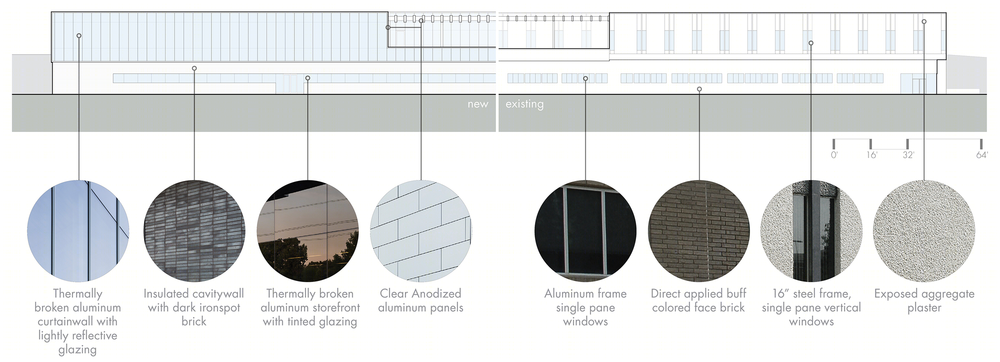

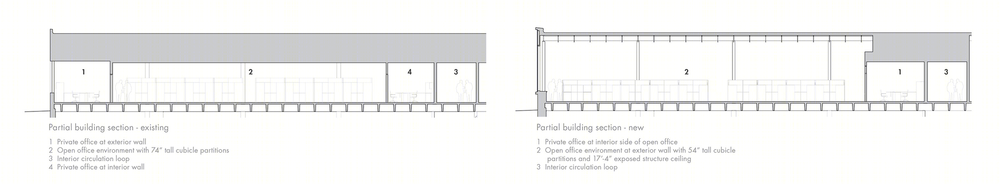

Knowing the company’s commitment to daylight, the design team proposed a replacement of 85% of the upper level exterior wall. The existing wall was constructed of uninsulated single wythe concrete masonry with a layer of exposed aggregate plaster on the exterior face. Two vertical 16” windows were paired about a structural column at 24’ on center. The primarily opaque assembly was replaced with thermally broken aluminum curtain wall with 1” thick argon filled insulating glass. The existing building is subdivided into 24’ x 48’ structural bays with 4’ on center steel joist spacing. This rigor was expressed in the repetitive spacing of curtain mullions at 4’-0” on center articulated by a custom extruded 1-1/2” aluminum fin capping the vertical joints.

The lightly reflective glass mirrors the lake, lawn, and trees along the east, north, and west façade. The new curtain wall volume is surrounded by a silver aluminum trim element that folds up and down to frame building entries and the east facing dining terrace. The upper level glass volume hovers lightly over a dark iron-spot brick base that mediates between glass and ground and negotiates the grade change along the north elevation.

The existing masonry base was constructed of an uninsulated single wythe concrete masonry wall with direct applied buff colored brick. The renovated wall extended the building foundation 8” to add insulation, air space and construction of a true cavity wall of dark brick. A continuous ribbon of glass at the base is set co-planar to the brick to visually fuse with the dark base. Subtle changes in brick coursing add a level of refinement at building entries.

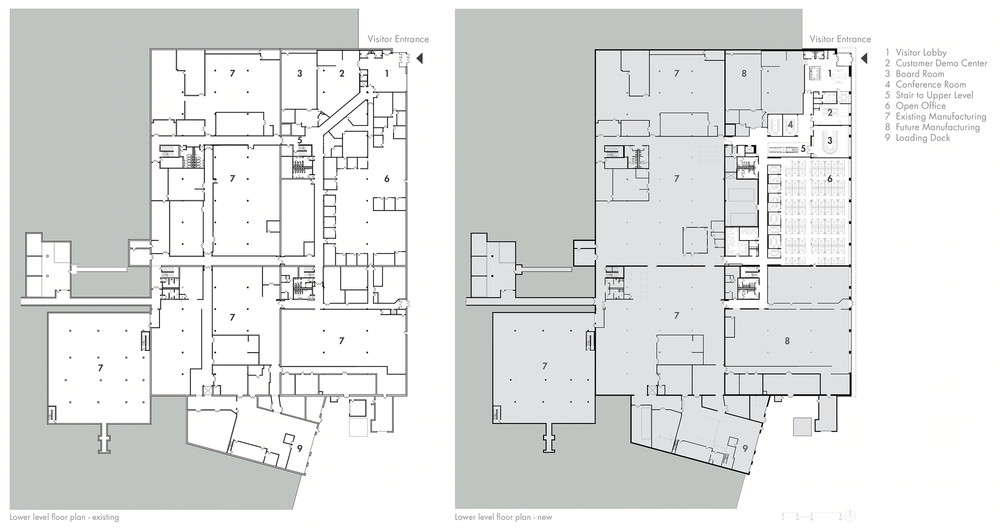

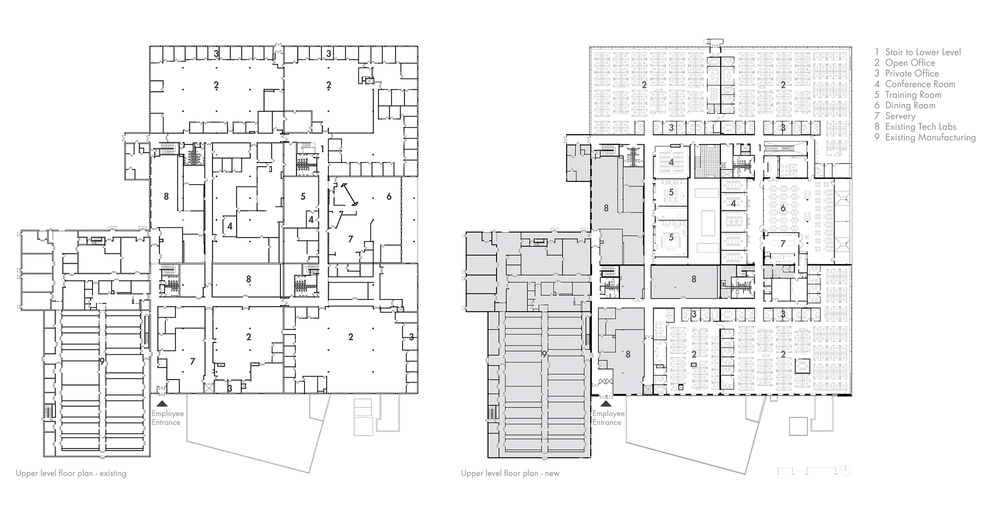

On the interior, Emerson leadership committed to a dramatic workplace culture change. Long established hierarchies (enclosed private offices along the exterior wall surrounding internal cubicles with full height partitions) were inverted. The resulting project replaced 28,000 square feet of exterior envelope and demolished/reconstructed 165,000 square feet of interior corporate office programs.

Emerson’s commitment to inverting traditional corporate hierarchies represented a profound cultural shift for corporate leadership and staff that was seen as a large-scale pilot project in the Eden Prairie project.To support the cultural change, the design team facilitated educational workshops discussing current research into generational and technological changes in the corporate workplace. Embracing workplace mobility, choice of flexible non-traditional work environments, spaces for informal meeting and collaboration, and design as an expression of company brand were all embraced as design goals.

The 120,000 square foot building footprint, ideal for manufacturing, poses challenges for office workplace environments. The design goal was to provide daylight and view to all office spaces by accepting an internal circulation loop inset 95’ from the new curtain wall. Areas adjacent to glass curtain wall were dedicated to open office environments with low proportioned workstations with glass dividers. Glass-fronted private offices were located inboard just inside the circulation loop. On the interior of the circulation loop, programs include glass fronted conference rooms, testing labs, training rooms, vertical circulation, toilets, and building mechanicals.

美国艾默生过程管理公司外部侧面实景图

美国艾默生过程管理公司外部局部实景图

美国艾默生过程管理公司外部实景图

美国艾默生过程管理公司外部夜景实景图

美国艾默生过程管理公司内部前台实景图

美国艾默生过程管理公司内部实景图

美国艾默生过程管理公司内部过道实景图

美国艾默生过程管理公司实景图

美国艾默生过程管理公司对比图

美国艾默生过程管理公司平面图

美国艾默生过程管理公司立面图