工业 4.0 时代的制造工厂 | 高品质设计与功能性并重

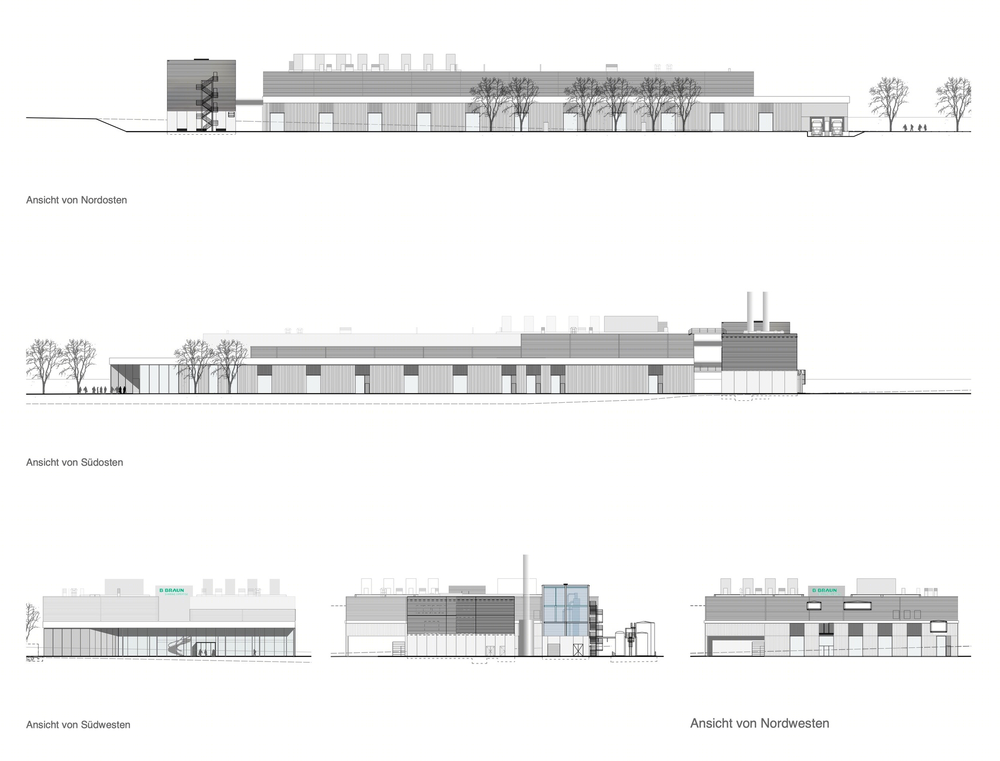

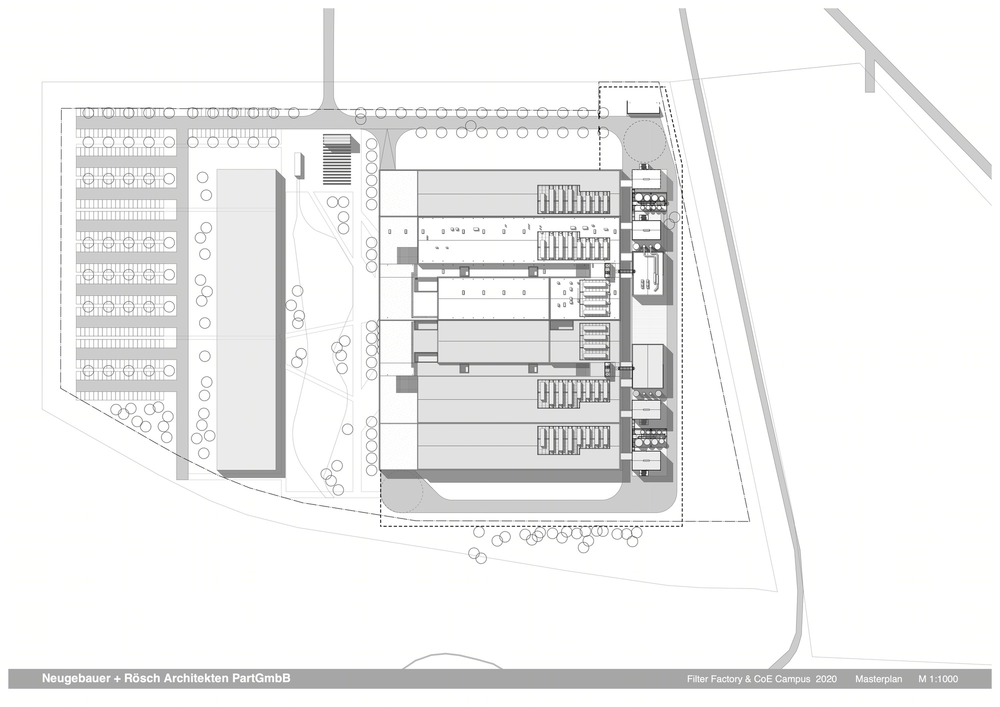

The new build is conveniently located close to the A4 to the west of Dresden. A manufacturing hall measuring 143 by 62 metres, where the dialysers are assembled under cleanroom conditions, is the main part of the project. Offices, areas for recreation and logistics, as well as a boiler house to the rear of the plot, complement the industrial estate. The plant with a gross floor area of 15,000 m² provides workspace for a total of 140 persons. The design submitted by Neugebauer + Roesch won the architecture design competition initiated by B. Braun. Among other things, the judges commended the “appropriate blend of representative appearance and functionality” in the planning practice’s proposal.

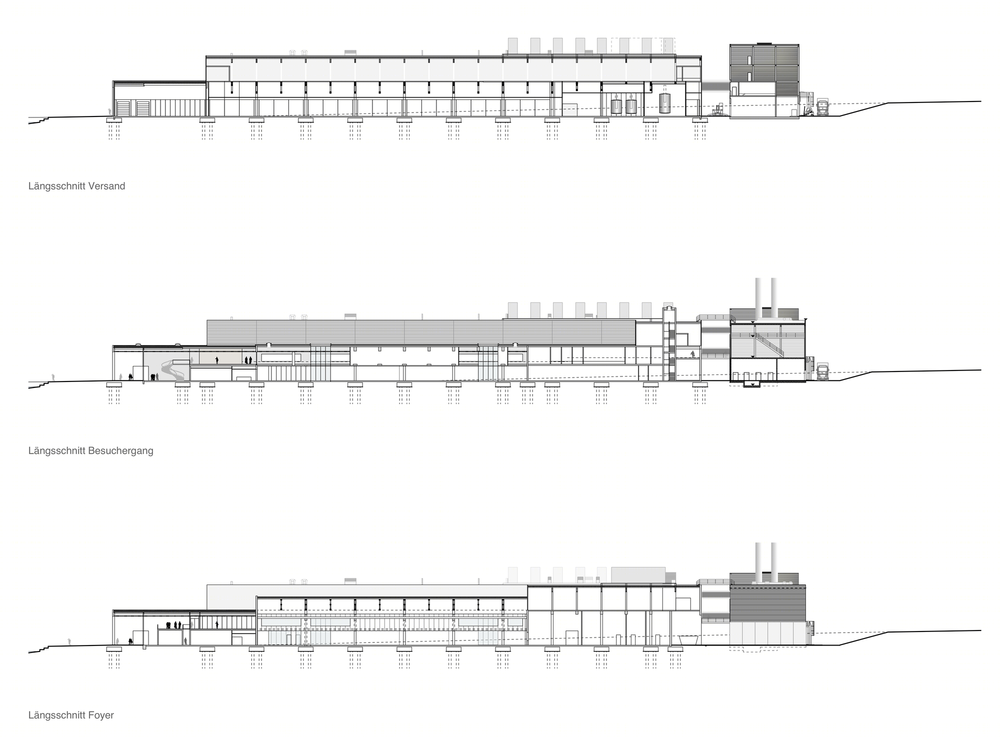

Clear architectural language with concrete, metal and glass. Exposed concrete, metal and glass characterise the new manufacturing plant. The clear, serene design concept applied by the Stuttgart architects is visible throughout the new build. A vast fully glazed facade enables the manufacturing plant to open out onto the forecourt, which visitors and staff members cross when approaching the building. The glass front facing the forecourt has been setback creating an inviting covered space at the entrance. Slender posts highlight the simple yet distinct style of the industrial building. The full-height glazing offers views into the foyer, the cafeteria and the gallery with access to the adjoining office zone.

Robert Rösch places great value upon the high-quality design of the building occupants’ working environment. He says, “The distinction between tasks performed at a desk in an office and at an assembly line in a production hall is vanishing. They are a part of each other and must therefore be conceived in the same way.” The office staff has access to a planted roof terrace for recreation during breaks. The planners have also included a link to the exterior space for the hermetically sealed cleanrooms in the hall’s interior: two courtyards allow daylight to penetrate the high-tech labs. The slate boulders there are a pleasant contrast to the sterile rooms and offer the employees working with protective clothing small visual retreats during the production of the dialysis filters.

A long tradition of high-quality architecture. Good industrial architecture has always been very important to the company B. Braun. For the new headquarters in Melsungen (1992), B. Braun commissioned the renowned architect Sir James Stirling. Professor Ludwig Georg Braun, a member of the founding family and now the supervisory board, will inaugurate the new filter manufacturing plant in Wilsdruff on 4 September 2018 in the presence of the Saxonian Minister President, Michael Kretschmer, and the Federal Minister of Health, Jens Spahn.

Exposed concrete plays an important role in B. Braun’s high-quality industrial buildings. This is particularly noticeable in the vast fair-faced surfaces of the new plant’s foyer, which were completed using system formwork. “These walls with their vibrant hues of grey characterise the appearance of the building’s entrance area,” explains the architect Robert Rösch. The large exposed concrete walls, which were also constructed according to the building’s 2.4-metre grid, correspond to the scale of the glass elements and the extensive in-situ terrazzo flooring.

Hybrid structure made of concrete and steel. The building can be considered a hybrid structure since it includes a blend of in-situ concrete, precast concrete elements and a steel framework. The structural backbone of the building, incorporating the visitor walkway and the central infrastructure, is a feat of civil engineering: it was conceived as a highly reinforced in-situ concrete construction to bear the horizontal loads from the extensive roof and facade areas. Large precast elements, also sized according to the 2.4-metre grid, characterise the exterior walls of the ancillary buildings, which accommodate the sprinkler system and other complex production technologies.