波浪之光 | 菲律宾工厂建筑的绿色改造

来自

Gene Miao

Appreciation towards

Gene Miao

for providing the following description:

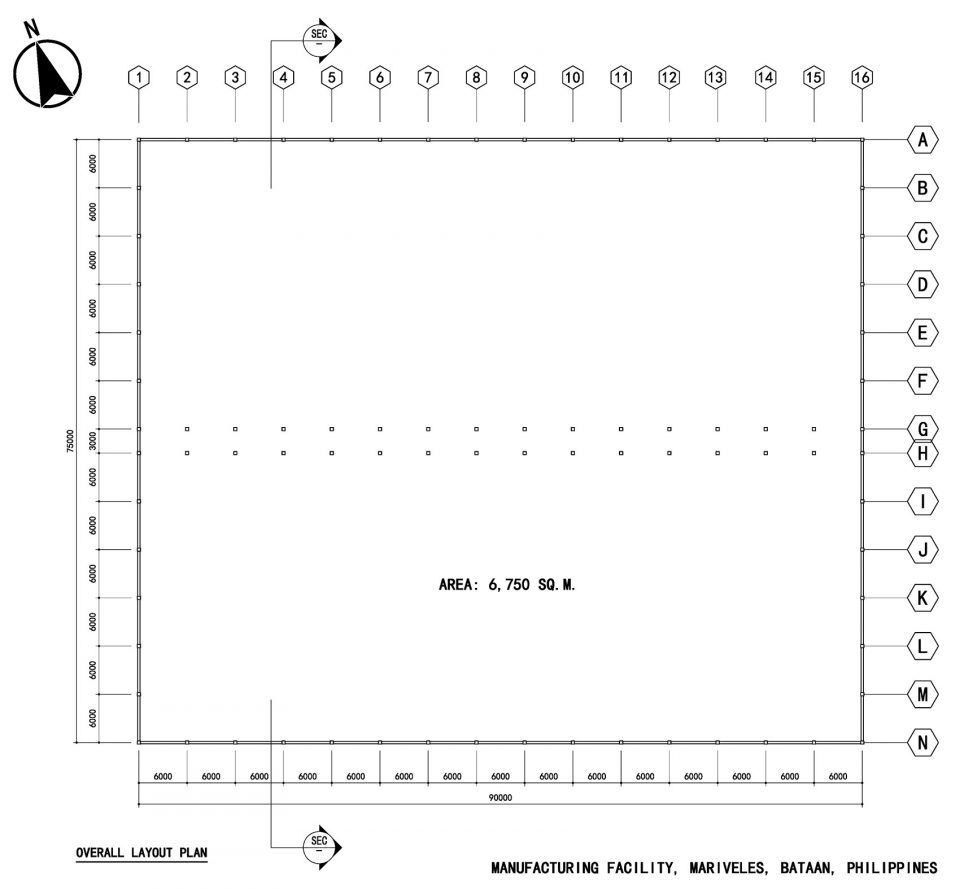

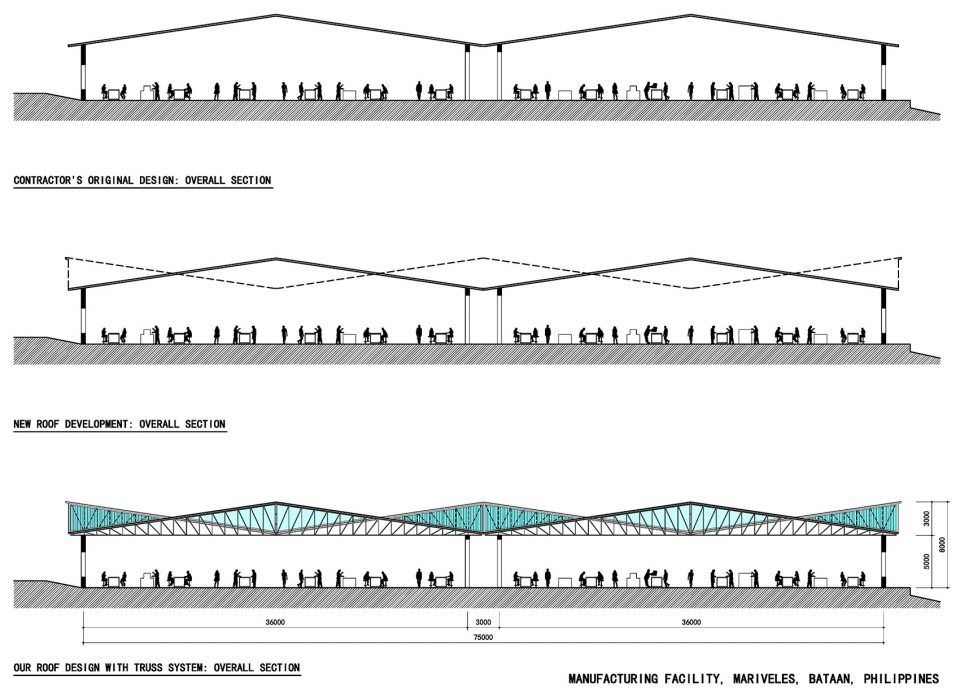

该项目位于菲律宾巴丹半岛的马里韦莱斯,是一家手提包制造商在原址上扩建的新工厂。建筑的体量为90×75米,占地面积约为6750平方米,与场地上既有的生产设施相连。既有的建筑是屋顶略微倾斜的巨大棚屋,自然光仅从侧墙上的一些小窗射入屋内。在原有的建筑内,即使装上更加靠近地面的荧光灯也无法改善生产空间的照明,更不用说还要耗费大量的人工照明成本。显然,设计的基本思路在于设法将自然光引入主要的生产区域,由于承包商已经开始动工,因此不能改变建筑的既有结构。在这些限制条件下,建筑师需要通过调整屋顶结构来解决核心照明的问题。建筑师从屋顶的双向坡度入手,尝试将屋顶的轮廓线分成行列并交错排布,在屋顶内形成一系列菱形和三角形的空间,从而使光线得以进入。最终,屋顶呈现出波浪般交叠起伏的形态。

1:1 was brought in to design a new factory building that would enable a handbag manufacturer to expand capacity on his current site in Mariveles, Bataan, Philippines. The new building measures roughly 90 x 75 meters in plan, for a total footprint of approximately 6,750 square meters, adjacent to existing manufacturing facilities on the same plot. The existing buildings are basically giant sheds with gently pitched roofs, with natural light entering only from small openings on the periphery walls. Given the design, even the presence of fluorescent lighting closer to the factory floor could not alleviate a relatively dark production space, not to mention the energy costs maintaining such artificial lighting. Clearly, a fundamental design question was how to introduce natural light to the main production space without changing the foundational structures, given that the contractor had already started work on these, before 1:1 joined the project. Given the constraints, we basically had to solve the core lighting problem with adjustments to the roof. Taking the engineer’s double- pitch roof design as the starting point for the project, we experimented with how to stagger the roofline’s pitches in rows, thereby creating a series of diamond and triangular openings within the roof where light could enter. The effect is rows of gently pitched roofs sliding past one another in a smooth undulating roofline.

▼项目旨在通过调整屋顶结构来解决核心照明问题,the projecct aims to solve the core lighting problem with adjustments to the roof

为了降低新屋顶的总重量和制造成本,建筑师用聚碳酸酯板构建了50个天窗 (其中30个是菱形,20个是三角形),使周围的自然光射入生产空间,形成宽敞而明亮的环境。总体而言,该解决方案在保证结构稳固性的同时,构建出了一个布局自由的开阔空间,不仅降低了电力消耗,还为工人们创造了一个更加明亮和有吸引力的工作空间。

To reduce the overall weight and cost of the new roof design, polycarbonate panels were used for the skylights, as they diffuse ambient natural light into the production areas to create a vast, inviting light-filled space. There are a total of 50 skylights, of which 30 are diamond-shaped; and 20 are triangular-shaped. In short, this solution is engineered for structural soundness, while maintaining a largely free-form production floor while using natural light to reduce electricity spend and create a brighter, more attractive workspace for the workers.

▼波浪般起伏的屋顶包含50个天窗,the undulating roofline consists of 50 skylights

在其它一些情况下,类似的屋顶结构可能需要立柱来提供垂直方向的支撑,但在该项目中,建筑师需要使用尽可能少的立柱来保证生产空间拥有最大的灵活度。建筑师与结构工程师共同设计了一个桁架结构,使建筑在不使用立柱或大型横梁的情况下也能够承受屋顶的重量。该桁架能够在生产空间上方横跨超过36米的距离,使建筑对生产的干扰降到最低。建筑中仅存的双排立柱位于矩形体量的中央,呼应了原先的设计,且不影响已经开始的地基工程。

In other circumstances, such a roofing structure might have required vertical columns as supports, but in this case, we needed to minimize the number of columns on the production floor, which afforded the owner maximum flexibility in the production space. Our design solution required working with a structural engineer to design a truss to address the loading overhead without the use of columns or thick beams that would block the light. Our truss design can span more than 36 meters across the production space, so that there is the least amount of obstruction for the production floor. The only remaining columns are a double row of columns in the middle of the rectangular space, which replicate the original design while not interfering with the ongoing footing work on site.

▼菱形和三角形的开口将自然光引入生产空间, a series of diamond and triangular openings within the roof where light could enter

▼桁架结构使建筑在不使用立柱或大型横梁的情况下也能够承受屋顶的重量,the truss can address the loading overhead without the use of columns or thick beams

▼桁架的跨度达36米,the truss design can span more than 36 meters across the production space

▼平面图,plan

▼剖面图(初始设计/新设计/桁架系统),sections (original/new/truss system)

Project size

6750 m2

Completion date

2017