- 项目名称:通快(中国)有限公司扩建数控平面激光切割机数控折弯机项目

- 项目地点:江苏省太仓市南京东路68号

- 项目类型:工业建筑

- 设计单位:中衡设计集团股份有限公司

- 施工单位:江苏金土木建设集团有限公司

- 业主:通快(中国)有限公司

- 用地面积:78001.09m2

- 建筑面积:32534.75m2

- 设计时间:2017.10.17-2018.4.

- 竣工时间:2019.4.10

- 主创建筑师:刘恬

- 设计团队:刘恬,赵海峰,路江龙,沈晓明,丁炯等

- 摄影:秦伟

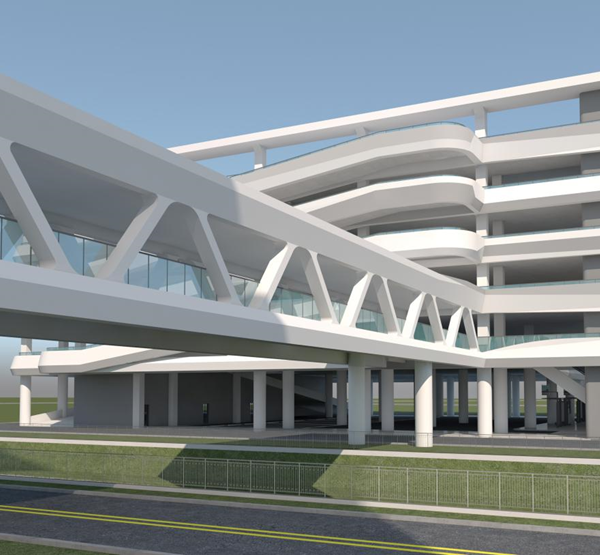

本项目位于苏州市太仓通快(中国)有限公司厂区内,共新建综合楼、车间和门卫及设备房三个建筑单体。其中,综合楼为设计重点。作为综合楼的主要功能空间,餐厅的主立面被精心打造。铝制外遮阳百叶的出色应用与相应周边场所的营造,呈现出工业建筑所特有的技术潜能和空间潜力。而项目背后,则是建筑师带领下的设计团队对工业建筑设计美学的独特理解与设计追求。

This project is based in TRUMPF Co., Ltd (Taicang, China),including complex, guard room and equipment room. The focus then was on the complex building. The dining room (multifunctional) is the main space of the complex and its façade has been carefully designed. The outstanding application of Aluminum external shading louvers, combined with the construction of the surrounding environment, shows the unique technical and spacial potential of industrial buildings. And behind the project is a specific understanding and pursuit of industrial aesthetics of the design team under the leadership of architects.

▼综合楼日景,the complex in daytime © 秦伟

▼综合楼主立面,the façade of the complex © 秦伟

由铝制梭形百叶组成的垂直感光电动外遮阳位于综合楼南立面,百叶总高11.1m,为国内已建电动外遮阳构件中的最高纪录。方形景观水池的环境组织是本项目场所营造的点睛之笔。在日光下,水池边的白色铝制百叶熠熠生辉,仿佛漂浮于水面之上;在夜晚,泛光照明下的铝制穿孔百叶,与水中倒影交相辉映。

The vertical photosensitive electric external shading system composed of aluminum spindle louvers is located on the south facade of the complex building. The total height of the louvers is 11.1m ,which is the highest record among the electric external sunshade components that have been built in China. The finishing touch of environmental design in this project is the arrangement of the square pool. In the sunlight, the shiny white aluminum louvers seem to float above the water at the edge of the pool;At night,aluminum louvers are illuminated by flood lighting and reflect in the water.

▼科技与轻盈:由铝制梭形百叶组成的垂直感光电动外遮阳与景观水池 © 秦伟 Technology and lightness:Vertical photosensitive electric external shading system composed of aluminum spindle louvers and the landscape pool

▼古典美:泛光照明下的铝制穿孔百叶与水中倒影 © 秦伟 Classical beauty: aluminum pertforated louvers under floodlight and reflections in the water

事实上,形式的轻盈背后是精细的工艺与复杂的构造。调控单片百叶的 控制马达位于百叶上部,被藏在空腔之中;泛光照明等构件则在底部预埋;水池与主体结构脱开,室内外高差通过石材饰面做平,以获得百叶底部的从室内、室外到水面的连续感和整体性。铝制梭形百叶的制作全部由通快自有的加工机床完成。作为全球制造技术领域的领导企业之一,通快集团拥有加工金属薄板的精湛工艺。细致的冲孔、辊压,使得百叶本身成为极具说服力的展品,正对厂区主入口的立面也成为了集团产品的大型展示墙面。材料、工艺、构造与环境的叠加,解除了“百叶”这个传统构件的重力束缚,赋予其科技感、轻盈感与古典美。

▼铝制百叶的工艺与构造,the craftsmanship and construction of aluminum louvers ©(左)秦伟,(右)中衡设计

Actually, what behind the lightness of the form is the elaborate craftsmanship and complex construction. The control motor that regulates the single louver is located on the upper part of the louver and is hidden in the cavity. The components of floodlighting and other are pre-embedded at the bottom. To obtain the continuity and integrity from the indoor and outdoor to the water,the pool is separated from the main structure, and the difference of the height is flattened by the facing stone. The production of aluminum spindle louvers is totally completed by TRUMPF’s own processing machine. As one of the world’s leading enterprises in the field of manufacture in the world, TRUMPF Group has exquisite craftsmanship for processing sheet mental. The meticulous punching and rolling make the louver itself a convincing exhibit. The façade facing the main entrance of the plant becomes a large display wall for the company’s products and technics. The superposition of materials, craftsmanship, construction and landscape, relieves the gravity constraint of the traditional component,and gives it a sense of technology, lightness and classicism.

▼具有科技感、轻盈感与古典美的铝制百叶,the aluminum louvers with a sense of technology, lightness and classicism © 秦伟

轻钢屋面向采光方向微微倾斜,以开放的姿态引入室外的光线、水池和草地。室内采光虽然借助了照明设备,但仿佛外部自然光线的延续。为实现室内外采光的连续性和均衡性,我们考虑光线的方向,谨慎选择吊顶上照明设备的放置方向和分布模式,并进一步将空调、吸音降噪、排烟与喷淋综合在几何分割的设备带,以保证室内体验的纯粹性。

The steel deck roof leans slightly towards the light,opening up to the outdoor light, pool and grass. The interior lighting, though with the help of lighting equipment, seems to be the continuation of the external natural light. In order to achieve the continuity and balance of indoor and outdoor lighting, we take the direction of light into consideration, and select the placement direction and distribution mode of lighting equipment carefully. In addition, to ensure the purity of spatial experience, the equipment of air conditioning,sound absorption and noise reduction,smoke exhaust and spraying has been further integrated into the geometrically divided equipment belt.

▼室内外采光的连续性和均衡性,the continuity and balance of indoor and outdoor lighting © 秦伟

作为厂区工业建筑的附属空间,综合楼以空间利用的多功能性为设计目标,集餐厅、展示、接待、办公、会议、培训等功能为一体。其中,餐厅作为大空间被视同为多功能厅。为实现其多功能性,综合楼实际上采取了混合结构,以获得纯粹的无柱大空间。呈L型布局的会议、办公、培训等小型功能空间为混凝土结构,直接支撑起了上部的钢结构屋面。内外流线被位于综合楼与厂房之间的连接体有效地分离。位于连接体中部的“木质圆环”,标识出了空间的内外性质。圆环外侧为入口门厅与访客接待,内侧则设置为洽谈区兼做小型展示区,可滑动调节的顶灯,结合可移动的小型展示台,获得了空间的灵活性。内部流线由连接体后部的外廊解决,生产空间的工人通过外廊至综合楼进行就餐,或参加培训、会议等活动。

As the ancillary space of the factory’s industrial buildings, the complex building is designed to be multi-functional, integrating functions such as dining, exhibition, reception, office, conference and training. The dining room, as a large space, is regarded as a multi-function hall. And in order to achieve this versatility, a mixed structure has been adopted actually to obtain a pure space without columns. Meanwhile, the small functional spaces such as meetings, offices, and trainings in an L-shaped layout are made of concrete structures, which directly support the upper steel structure roof. The connected volume between the complex and the plant separates the internal and external circulations effectively. In the middle of it,the“wooden ring” marks the interior and exterior nature of the space. The outer side of the ring is the entrance hall and visitor reception, while the inner side is set as a flexible area for negotiation and small exhibition with movable tables and sliding lights. The outer corridor at the back of the connected volume, provides space for the circulation inside, through which the workers can go for dining, training and meetings directly.

▼“木质圆环”:标识出了空间的内外,the wooden ring marks the interior and exterior nature of the space © 秦伟

▼功能灵活的洽谈区,the inner side is set as a flexible area for negotiation and exhibition © 秦伟

设计的精细度决定了空间的纯粹性。综合楼看似简单的表象之下,实际上需要建筑师在设计过程中对构造细节持续不断的关注。一方面,建筑师需协调结构、机电专业,将控制马达、钢结构支撑构架紧密配合安装于铝板幕墙系统与ALC外墙之间,以实现外部的纯粹;另一方面,根据对应空间的特质采用相应的吊顶分割方式,并结合设备带进行管综设计,以保证室内外的连续性。

The precision of the design determines the purity of the space. Beneath the simple appearance of the complex,it actually requires the architect to pay constant attention on the architectural details during the design process. On the one hand, in order to achieve the purity, the architects should integrate the control motor into the steel structural support frame and install it between the aluminum curtain wall system and the ALC elevation, working closely with the structural and electromechanical engineers. On the other, in order to ensure the continuity outside and inside, it is necessary to adopt the corresponding division method of ceiling according to the characteristics of the space, combining with the comprehensive design of pipes by the application of the equipment belt.

▼室内吊顶的分割方式,the division of ceiling © 秦伟

此外,模数化理念的运用,有效控制了空间和立面的比例,提升室内外空间的美学品质的同时,显著降低建筑构配件的定制、施工周期和维护更换成本。

In addition, the application of the modular concept, controlling the proportion of space and façade effectively, improves the aesthetic quality of space,and reduces the cost of customization and maintenance of architectural components, and shortens the cycle of construction as well.

▼后部外廊,the outer corridor at the back © 秦伟

▼综合楼夜景,the complex at night © 秦伟

在对整体感、纯粹感、细节感的把握和追求之中,设计团队把厂区里原本不起眼的附属建筑变成了一个富有艺术性的“展品”。无论白天还是夜晚,都令人印象深刻。

In the pursuit of purity and the control of the details,the design team transformed the originally unimpressive ancillary building into an artistic “exhibit”. Whenever day or night ,the complex is impressive.

▼总平面图,site plan © 中衡设计

▼一、二层平面图,the 1st and 2nd floor plan © 中衡设计

项目名称:通快(中国)有限公司扩建数控平面激光切割机数控折弯机项目 项目地点:江苏省太仓市南京东路68号 项目类型:工业建筑 设计单位:中衡设计集团股份有限公司 施工单位:江苏金土木建设集团有限公司 业主:通快(中国)有限公司 用地面积:78001.09m2 建筑面积:32534.75m2 设计时间:2017.10.17-2018.4. 3 竣工时间:2019.4.10 主创建筑师:刘恬 设计团队:刘恬,赵海峰,路江龙,沈晓明,丁炯等 摄影:秦伟 文稿:延续建筑创作研究中心 陈婷

Project Name: TRUMPF (China) Co., Ltd Taicang Extension Project Project location: Taicang,Jiangsu Architecture Firm: ARTS Group Co., Ltd. Engineering: Jiangsu Gold Civil Construction Group Co., Ltd Clients: TRUMPF (China) Co., Ltd Site area: 78001.09m2 Gross Built Area: 32534.75m2 Completion Year: 2019 Lead Architects: Liu Tian Design Team: Liu Tian,Zhao Haifeng, Lu Jianglong, Shen Xiaoming, Ding Jiong,etc. Photo credits: Qin Wei Author & Editor: Chen Ting

{{item.text_origin}}