© Toshihiro Sobajima

(3)Sobajima Toshihiro Sobajima

现场和客户的简报--115.8 平方米的场地-- 坐落在一条繁忙的工业街道上,项目是重建现有的钢结构仓库/办公大楼。

The Site and the Client’s Brief

The 115.8 m2 site sits along a busy industrial street, and the program was to rebuild the existing steel structured warehouse / office building.

© Toshihiro Sobajima

(3)Sobajima Toshihiro Sobajima

由于毗邻一条宽阔的街道,这座建筑的优点是可以方便装卸、数量和大小、所经营的商品和场地也是一个拐角处,这座建筑将从周围的环境中脱颖而出。另一方面,缺点是白天持续的噪音,交通拥挤引起的震颤,以及极强的一周地面力量。

Being adjacent to a wide street, the advantages of this site were accessibility with an ease of loading and unloading, quantity and size wise, the merchandize they deal in and the site also being a corner site, the building would stand out from the surroundings. On the other hand, the disadvantages were the continuous noise during the day, together with the tremors caused by heavy traffic and also the extremely week ground strength.

客户公司是一家中等规模的零售商,负责处理大量的螺母和螺栓以及其他建筑材料。他们要求新总部具备仓库、陈列室和办公室的功能,并成为一种有趣、吸引眼球的建筑。然而,预算是非常有限的,约 60%(约 240 至 250 日元每平方米) 的平均混凝土建筑。通过全面分析客户的要求,并以尽可能低的成本和形象的最终结构,我开始研究的可能性,与我的同事,结构工程师和承包商。

The clients’ company is a moderate size retailer handling a vast range of nuts and bolts together with other architectural materials. They requested the new headquarters to have the function of a warehouse, showroom and an office; and to be an interesting, eye-catching piece of architecture. However, the budget was extremely limited, at about 60% (about 240-250K yen per square meter) of an average concrete building. Through analyzing the clients’ requests thoroughly and with the minimum possible cost and the image of the final structure in mind, I began studying the possibilities together with my fellow structural engineer and contractor. © Toshihiro Sobajima (3)Sobajima Toshihiro Sobajima

通过合作创造,为了降低建筑成本,我考虑使用木结构和钢结构,希望能使建筑变得更轻,以适应软弱的地面条件。但经过一些研究后,我发现这些选择,虽然较轻,但在成本上并没有很大的不同。考虑到所有因素,最后的决定是采用混凝土,因为它具有防火和隔音的好处。

(3)Sobajima Toshihiro Sobajima

Creation through Collaboration In order to lower the building-cost I considered using wood structure and steel structure in hope of making the building lighter to correspond to the weak ground conditions. But after some studies, I found out that these options, although lighter, did not make much of a difference cost-wise. All things considered, the final decision was made to go with concrete for its fireproof and soundproof benefits.

© Toshihiro Sobajima

我很有信心这个项目是可行的,尽管预算有限,因为我能够与我的合作者从第一阶段就开始工作。我与建筑工程师佐藤军 (Jun Sato) 合作了 15 年,房屋建筑有限公司 (Home Builders Ltd.) 负责人松冈茂树 (Shigeki Matsuoka) 与我合作了 25 年,共建造了 80 多个项目。我也认识大部分在现场工作了很长时间的成员。

I was very confident that this project was feasible despite the limited budget because I was able to work with my collaborators right from the very first stages. I have worked with structural engineer Jun Sato for 15 years, and the contractor Shigeki Matsuoka, head of Homebuilder Co., Ltd., has been my collaborator for 25 years, building more than 80 projects together. I also knew most of the members working on site for a long period of time.

© Toshihiro Sobajima

(3)Sobajima Toshihiro Sobajima

一旦我们决定采用具体办法,松冈先生和我就编制了 20 多个类别的详细清单,并在其中分配了总费用,以便决定适当的材料和建筑细节,这是一种独特的方法,与设计和估算费用的正常程序完全相反。

(3)Sobajima Toshihiro Sobajima

As soon as we decided to go with concrete, Mr. Matsuoka and I created a detailed list of more than 20 categories and allocated the total cost among them in order to decide on the appropriate materials and architectural details, which is a unique approach and quite the opposite process from normal procedures of design and estimation of cost.

© Toshihiro Sobajima

两位著名的佛像雕塑家,在 12 世纪末至 13 世纪初活跃于日本佛像,为了追求这一必然或意义和建筑的活力,文中援引他们的话说,他们不是自己创造形状,而是“挖掘”嵌在木片中的形状。我们的设计过程在本质上与两位大师雕刻家的设计过程相似。

In Pursuit of the Inevitable or What Was Meant to Be and Dynamism in Architecture

Unkei and Kaikei, two famous Japanese sculptors of Buddha statues who were active in the late 12th to the early 13th centuries, are quoted to have said that they do not create the shapes themselves but rather ‘excavate’ the shapes embedded in the pieces of wood. Our design process followed a similar path in nature to that of the two master sculptors.

© Toshihiro Sobajima

(3)Sobajima Toshihiro Sobajima

我渴望实现一种强大、简单但又复杂的形式,比如螺栓,这些产品赋予公司名称“Boltun Co.,Ltd.”(Bolt 和 NUT 向后拼写),为了寻找合适的形式,我制作了无数的研究模型。我的目标是用“nuke(noo-Kay)*”创建三维连接的空间,使用连续的墙壁,就像一幅存在于一片建筑中的一笔画。

Aspiring to achieve a powerful, simple yet complex form like bolts, products that gave the company its name “Boltun Co., Ltd.,” (BOLT and NUT spelled backwards) I made numerous study models in search of the right form. My goal became to create 3-dimensionally connected spaces with “nuke (noo-kay)*” using continuous walls like a one-stroke drawing existing in one piece of architecture.

© Toshihiro Sobajima

(3)Sobajima Toshihiro Sobajima

另外,为了把建筑重量减少到 60% 的普通结构的这种类型,我削减了尽可能多的混凝土从盒子-- 框架结构。在我眼前出现的结果是一种独特的结构,类似于哈密瓜的网状皮肤。这是我以前从未见过的东西,平静而精致,就像我在结构中雕刻出了佛陀一样。开口采用玻璃化,安装镀锌钢楼梯,设计简约的悬吊扶手,避免削弱结构的动力和宁静。我还设计了一些内置家具仅使用劳安胶合板,一种材料主要用作衬垫和背板。

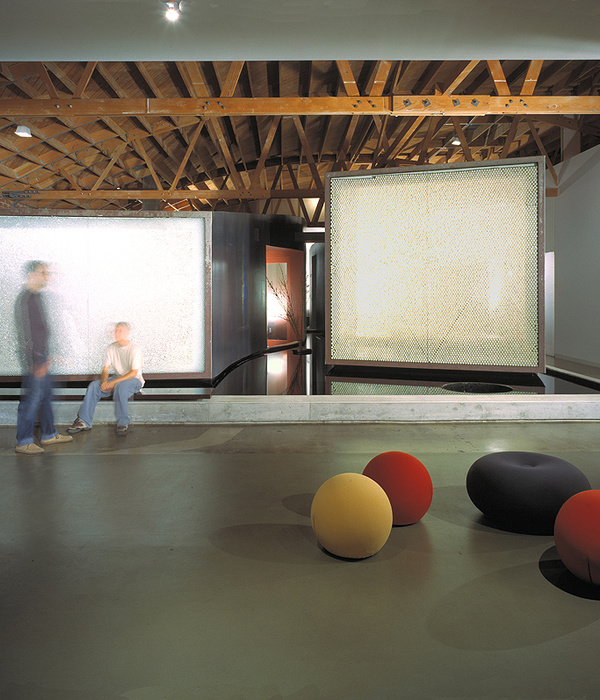

Also, in order to reduce the building weight to 60 percent of a regular structure of this sort, I shaved off as much concrete as possible from the box-frame structure. The result that emerged before my eyes was a unique structure resembling the mesh-like skin of a cantaloupe. It was something I had never seen before, serene and refined as if I had carved out the Buddha in the structure. The openings were glazed, galvanized steel stairs were installed, and minimalistic suspended handrails were designed with the utmost care not to diminish the power and serenity of the structure. I also designed some built-in furniture using only Lauan plywood, a material mainly used as underlayment and backer boards.

© Toshihiro Sobajima

(3)Sobajima Toshihiro Sobajima

当业主、承包商和我一起检查已完成的建筑时,有人发表了我完全同意的意见,即这个新总部散发出的活力和新鲜感与 Boltun 有限公司的公司形象是完全吻合的。

When the client, the contractor and I checked the completed architecture together, someone made a comment to which I totally agreed, that the dynamism and freshness this new headquarters exudes truly matches the corporate image of Boltun Co., Ltd.

© Toshihiro Sobajima

(3)Sobajima Toshihiro Sobajima

Architects Yasuhiro Yamashita x Atelier TEKUTO

Location Saitama, Japan

Lead Architects Yasuhiro Yamashita, Kenji Mizukami, Fumi Otosaka / Atelier TEKUTO

Area 155.79 m2Project Year 2018

Photographs Toshihiro Sobajima

{{item.text_origin}}