德克萨斯州首个大众林木建筑 | The Soto

Architect:BOKA Powell Lake|Flato

Location:San Antonio, TX, United States

Project Year:2020

Category:Offices

Stories By:BOKA Powell StructureCraft

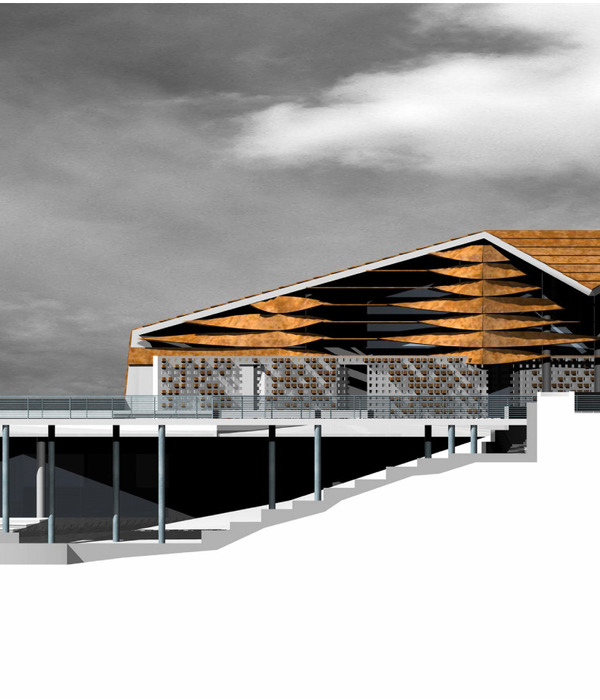

BOKA Powell, in partnership with Hixon Properties and Lake Flato Architects, is proud to present The Soto—Texas’ first mass-timber office building. Mass timber is a model for sustainable design and construction that has proven its strength in Europe, Canada, and Australia, and more recently, the United States. This elegant structure anchors the Cavender Neighborhood, an exciting new mixed-use project in the up-and-coming Broadway corridor of San Antonio.

The entire development focuses on efficiency, sustainability, flexibility, and innovation. Soto is the Spanish (Castillian) word for a “grove of trees” or “small forest,” especially one near a river, or a place of dappled sunlight and lush greenery.Soto is a name, a place, and an acknowledgment of this building’s origin. Not only is timber construction beautiful, but it is also exceptionally sustainable. Concrete and steel buildings have large carbon footprints, whereas The Soto’s timber structure is carbon negative. As young-growth trees are harvested for the building’s construction, the carbon dioxide absorbed into the wood is captured.New trees are then planted, and the cycle of carbon-banking is repeated. This LEED-certified structure is comprised of five stories of DLT (dowel-laminated timber) timber over one story of concrete.

Exposed floor and roof decks create a richness found only from natural products and welcoming timber columns, beams, and ceilings bring a calming charm and warmth to the workspace. The result is an environment and aesthetic that is distinctly differentiated from any other office space in the market. One of the distinguishing features of The Soto is its full-depth brick facade, making it one of the first North American projects to combine mass timber with masonry.

Benefits of Mass Timber*

• Lower cost: mass timber construction is more cost-effective than alternative forms of construction for mid-and high-rise buildings.

• Energy efficiency: building with mass timber is less energy-intensive than building with steel and concrete.

• Faster construction: by using prefabricated wood panels, mass timber construction is often faster than building with steel and concrete.

• Displaces steel and concrete: by reducing demand for steel and cement, mass timber construction reduces emissions from those hard-to-abate sectors.

• Disaster resistance: engineered mass timber products are fire-resistant, and mass timber buildings can handle earthquakes better than traditional high-rise construction.

• *SOURCE: American University Institute for Carbon Removal Law and Policy Carbon Removal Fact Sheet on Mass Timber Construction

The 6-storey, 168,000 sqft Soto Office Building gives San Antonio its first mass timber project. This elegant structure is in the first phase of a sustainable, walkable urban neighborhood project at Broadway and 8th streets.

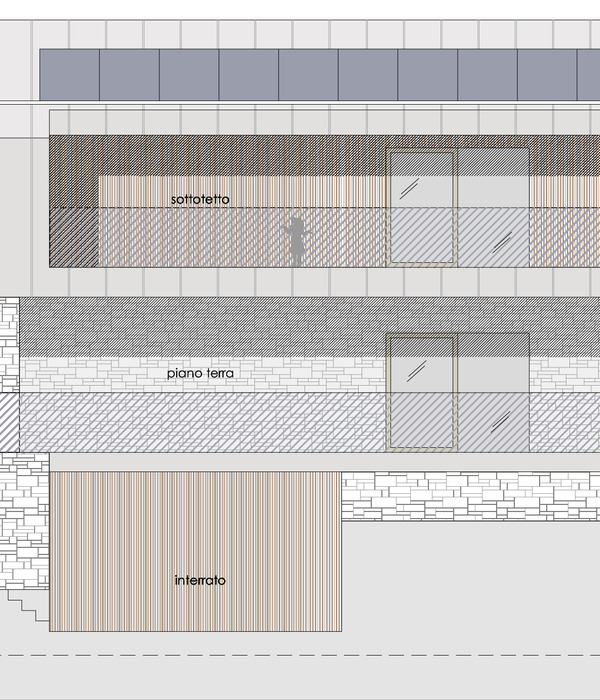

Constructed with 5 storeys of timber structure over 1 storey of concrete, this office building uses

DLT (dowel-laminated timber)

panels for the exposed floor and roof decks, supported by a Glulam post and beam frame. One of the features of The Soto is its full depth brick facade, making it one of the first North American projects to combine mass timber with heavy brick - this presented design challenges which the engineering team successfully solved.

Structural Engineering

StructureCraft

was engaged as engineer of record, working closely with Boka Powell and Lake Flato. The whole design team worked smoothly to bring this timber building to life.

Prefabricated DLT panels comprise the roof deck, each of the narrow 1.5" boards being moulded with a small chamfer to add texture and definition to the exposed ceiling. Against the San Antonio skyline, the cantilevered double height roof exquisitely showcases the use of timber..

The typical floor gravity structure uses these mass timber panels supported by a Glulam post and beam frame, with the columns set at a 20' x 30' grid. An under-floor air distribution system gives building occupants an unencumbered view of the timber ceiling and direct air control.

Engineered to minimize costs, the timber connection detail designs also emphasized constructability and tolerance. With the concrete core sustaining lateral loads and the gravity structure comprised of timber, the glazing and a heavy brick facade harmoniously envelope the wood structure.

The Soto is one of the first North American projects to combine mass timber with a masonry facade. This presented significant design challenges, combining timber - a material which has an inherent tendency to creep - with brick, a material which is particularly sensitive to deflection. The challenge was successfully solved through precise detailing that prevents long-term deflection and allows for a high-tolerance connection between the brick and mass timber system. At the loft roof, two-way 10' cantilevers comprised of DLT panels were created with a complete concealed connection system. This unique cantilever system showcases the beauty of the exposed timber through to the building exterior.

DLT floors help to provide additional acoustical and vibration isolation between stories. On top of the floor panels is 1" of concrete followed by a raised floor system with a 6" air cavity and 1" concrete floor tiles that are covered in carpet.

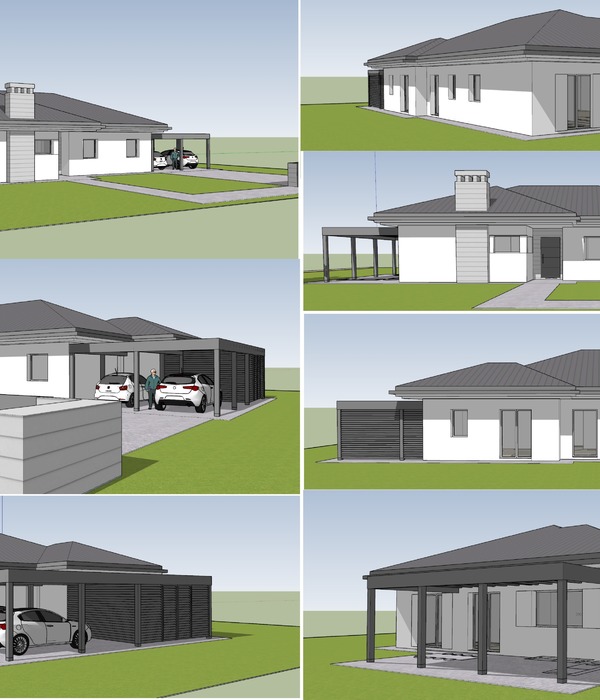

Fabrication

The timber panels were prefabricated in 8' x 60' sections, allowing for rapid installation. A honey brown stain was applied to the panels, creating warmth within the building space. The exterior Glulam canopies and terrace feature an architectural grade Larch species coated with a similar stain. A membrane applied after fabrication was used atop the panels to provide temporary moisture protection during construction. This system successfully protected the panels from significant moisture exposure during rain events.

Installation

The mass timber frame was erected following the cast-in-place concrete core. Large 60’ DLT panels allowed the floor plates to be completed rapidly and stitched together. A special feature of this building is the above-mentioned brick façade that, along with the glazing, wraps the wood structure. The brick trades worked well alongside the timber install team to provide seamless installation of both components.

▼项目更多图片