扎哈·哈迪德创新之作 | KnitCandela 超轻针织混凝土壳体

KnitCandela是一个薄薄的曲面混凝土壳体,框架由超轻的针织物构成。针织物部分在瑞士制作,用行李箱带到墨西哥。

KnitCandela is a thin, sinuous concrete shell built on ultra-lightweight knitted formwork that was carried to Mexico from Switzerland in a suitcase.

▼概览,overview

整个结构在墨西哥国立自治大学当代艺术博物馆进行组装,作为Zaha Hadid工作室在拉丁美洲的第一个展览。该项目是一个实验性结构,致敬了西班牙墨西哥建筑师兼工程师Félix Candela。设计师通过采用新的计算机设计技术和创造性的KnitCrete编织技术来重新构想Félix Candela别出心裁的混凝土壳结构。该项目动感的壳状结构是受到哈利斯科(墨西哥太平洋岸的州)传统服饰的流线造型启发。建造工人们亲切地称它为“sarape”(一种起源于墨西哥的条纹围巾),但事实上它的灵感来源于Félix Candela备受称赞的餐厅项目,在其后来的作品中也延续了同样的设计语言。

▼概念设计研究,conceptual design study

Constructed at the Museo Universitario Arte Contemporáneo (MUAC) in Mexico City as part of Zaha Hadid Architects’ first exhibition in Latin America, KnitCandela is an experimental structure that pays homage to the Spanish-Mexican architect and engineer Félix Candela. KnitCandela reimagines his inventive concrete shell structures through the introduction of new computational design methods and innovative KnitCrete formwork technology. The dynamic geometry of KnitCandela’s shell is inspired by the fluid forms of the colourful traditional dress of Jalisco, Mexico. While the structure’s local builders nicknamed the project ‘sarape’ (a striped scarf that originated in Mexico), KnitCandela’s form references his acclaimed restaurant at Xochimilco; a concept he further developed in several of his subsequent projects.

▼动感的壳状结构,the dynamic geometry of KnitCandela’s shell

Candela建筑师结合夸张的曲面造型(“hypars”),创造可以再利用的结构,来减少建造过程中的浪费。现在设计师可以通过KnitCrete技术考虑更加自由的造型设计,这个制作索网和纤维框架的系统可以高效地制作出更具有表现力的混凝土结构,不再需要复杂的建模。薄薄的双曲面混凝土结构表面积约为50平方米,重量超过5吨,但为其提供支撑的KnitCrete纤维框架仅重55千克,仅靠行李箱就能从瑞士运到墨西哥。

While Candela relied on combining hyperbolic paraboloid surfaces (“hypars”) to produce reusable formworks leading to a reduction of construction waste, KnitCrete allows for the realisation of a much wider range of anticlastic geometries. With this cable-net and fabric formwork system, expressive, freeform concrete surfaces can now be constructed efficiently, without the need for complex moulds. KnitCandela’s thin, double-curved concrete shell with a surface area of almost 50 sq.m. and weighing more than 5 tonnes, was applied on a KnitCrete formwork of only 55 kg. The knitted fabric of the formwork system was carried to Mexico from Switzerland in a suitcase.

▼纤维结构编织过程,knitting fabric process

该项目的纤维结构总面积50平方米,由四个15米到26米的长条组成。这四个长条都是单独制作的无缝合线双层纤维。双层的纤维可以满足不同的建造需求。外表面设计满足了技术上的需求,可以插入其它元素来固定、控制纤维结构位置。

The 50 sq.m. of textile shuttering of KnitCandela’s formwork is comprised of four long strips ranging from 15 m to 26 m in length. Each of the four strips is a seamless, double-layered textile produced as a single piece. Two layers of textile fulfil different tasks. The visible inside is an aesthetic surface that displays a colourful pattern and reveals traces of the supporting cable-net falsework system. The exterior surface fulfils technical requirements by including features for inserting, guiding and controlling the position of additional formwork elements.

▼内外不同的纤维层,different textile of interior and exterior

▼内部纤维细部,detail of the interior fabric

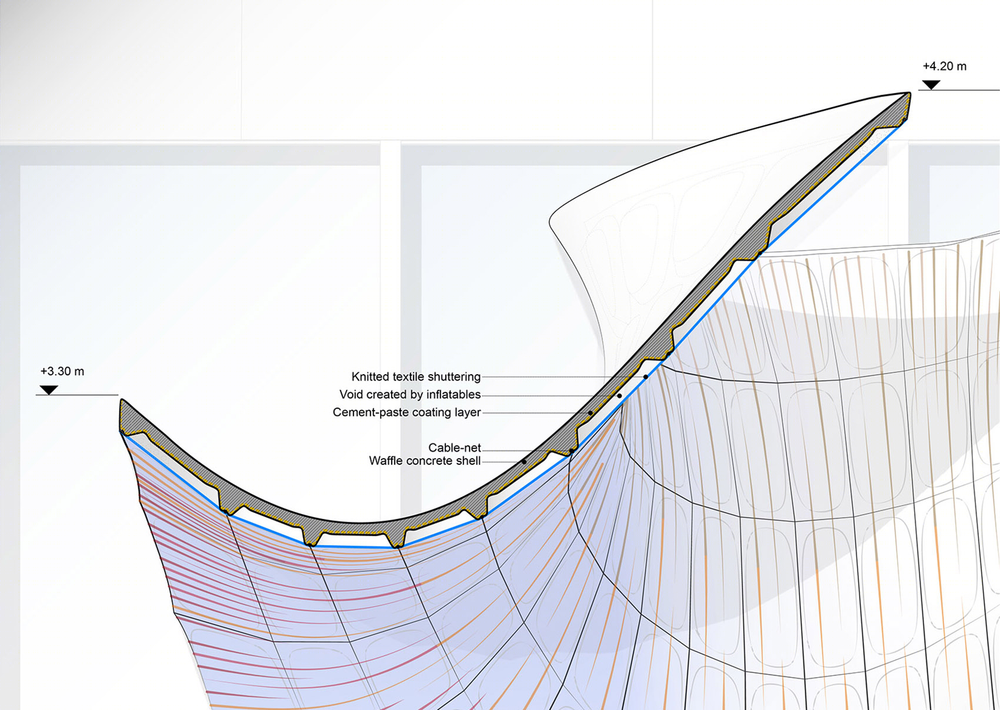

两层纤维间的空隙在编织过程中使用模具气球制作,作为浇筑混凝土时的预留空隙,不再需要复杂又造成浪费的建模工序。空隙位于纤维结构的外层,通过不同的针织密度控制空隙的形状大小,浇筑前插入模具气球,从而使不同方位的预留孔保持同样的标准大小。

▼设计和施工过程,design and engineering

The pockets created between the two layers as part of the spatial knitting process are inflated using standard modeling balloons. These inflated pockets become cavities in the cast concrete, forming a structurally efficient waffle shell without the need for a complex, wasteful formwork. Pockets located on this exterior side of the textile have different knit densities to control the inflated shape and openings for the insertion of the balloons, enabling cavities of different dimensions to be created with one standard balloon size.

▼结构分析图,structure analysis

▼建造过程,construction process

KnitCandela柔软多彩的内部纤维结构和外部坚硬的混凝土结构从各个角度都可以看到。纤维上的条形构造展现了它的织造过程还有镭射状的对称图案。柔软的内在和坚硬的外在可以同时出现在来访者的视野当中,提升空间体验,增加项目的造型曲度。

The soft, colourful textile interior of KnitCandela’s shell and its hard, concrete exterior is visible from all viewing angles. The textile’s striped pattern expresses the knitting fabrication process and the radial symmetry of the shape. This patterning, along with the simultaneous visibility of the soft interior and the hard exterior of the shell enhances the visitor’s spatial experience and the curvatures of the KnitCandela’s form.

▼细部,detail

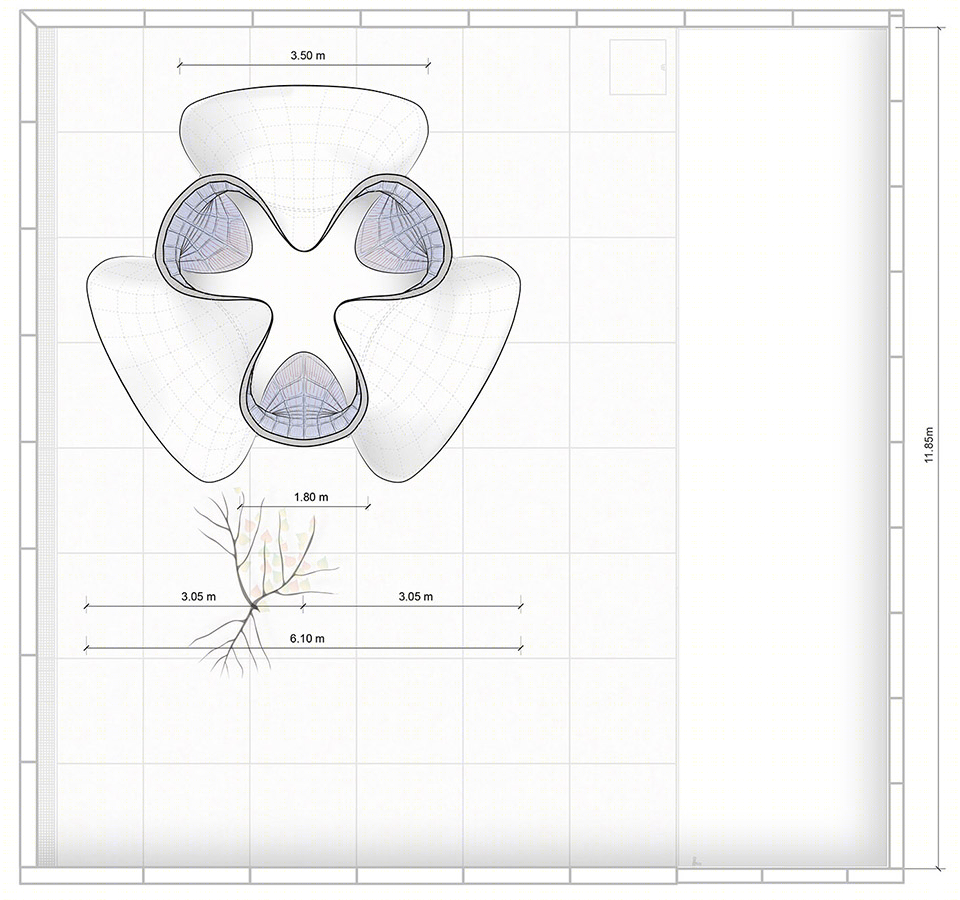

▼平面图,plan

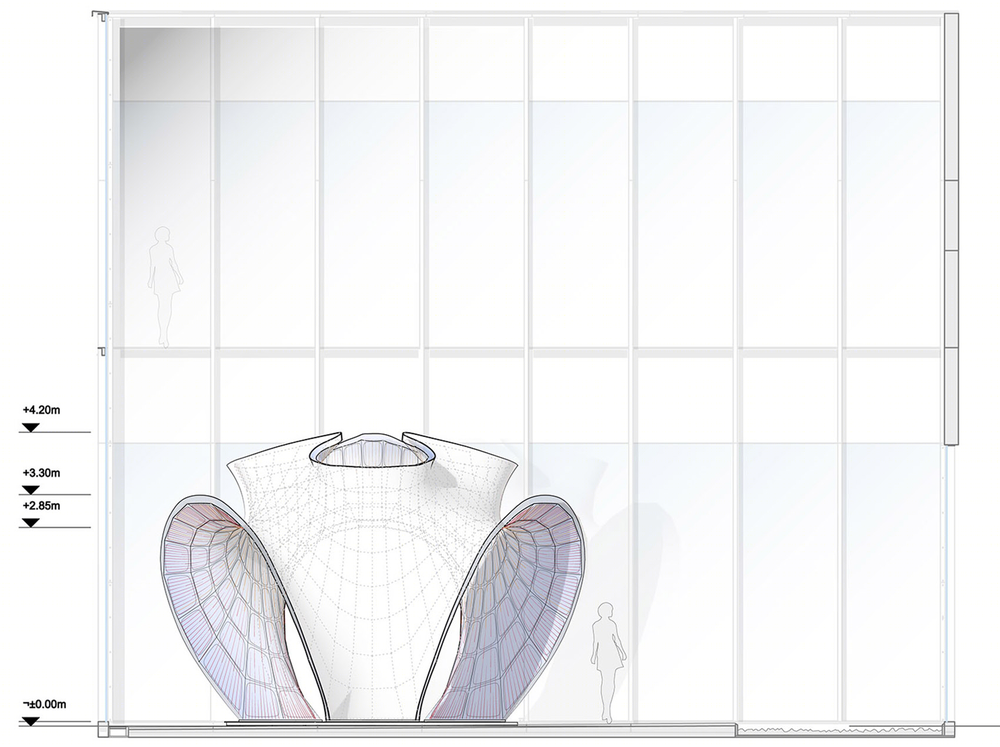

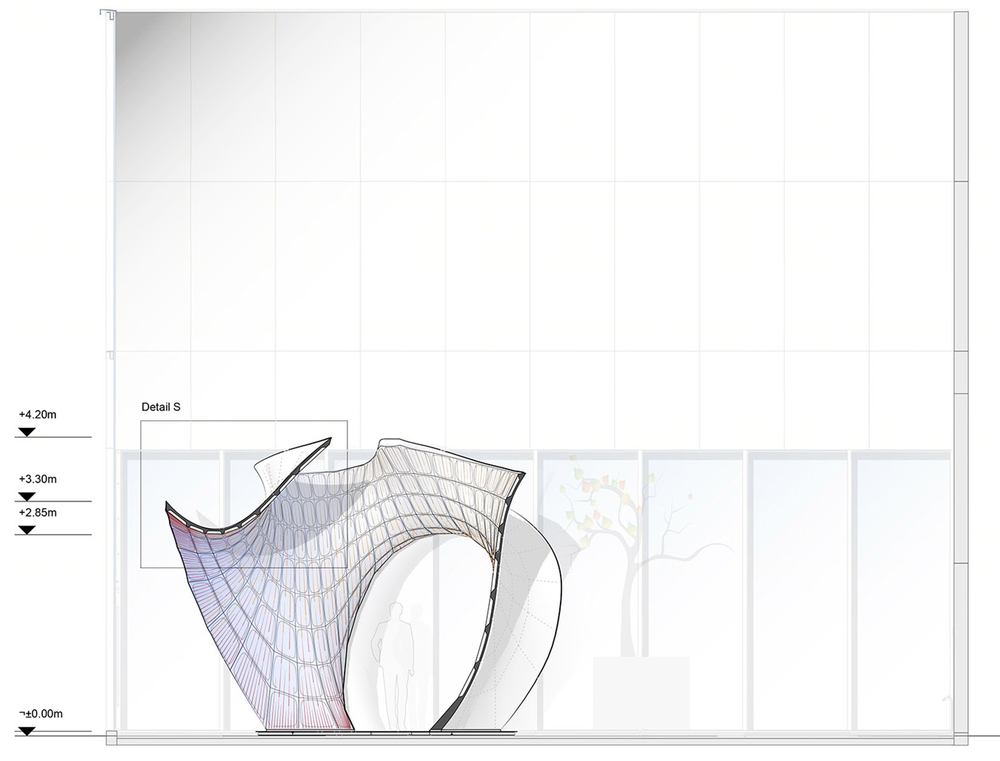

▼立面图,elevation

▼剖面图,section

KnitCandela Fact sheet Global dimensions shell: 5.8m x 5.8m x 4.1m Surface area of concrete: 47.5 sq.m. Weight concrete: 5 tonnes Weight formwork: 30 kg (cable net) + 25 kg (knit) Total length yarn: 350 km Type of yarn: Polyester (PES) Total amount of loops: 14’660’028 Knitting time: 36 hours Modelling balloons used: 1000 Project Team: Block Research Group, ETH Zurich (BRG) , Zaha Hadid Computation and Design Group (ZHCODE) , Architecture Extrapolated (R-EX) Design : Zaha Hadid Architects: Patrik Schumacher, Principal; ZHCODE: Filippo Nassetti, Marko Margeta, David Reeves, Shajay Bhooshan; BRG: Mariana Popescu, Matthias Rippmann, Tom Van Mele, Philippe Block KnitCrete technology : BRG: Mariana Popescu, Tom Van Mele, Philippe Block ; Chair of Physical Chemistry of Building Materials; ETH Zurich: Lex Reiter, Robert Flatt Fabrication and construction :BRG: Mariana Popescu, Matthias Rippmann, Alessandro Dell’Endice, Cristian Calvo Barentin, Nora Ravanidou ; R-EX: Horacio Bibiano Vargas, Jose Manuel Diaz Sanchez, Asunción Zúñiga, Agustín Lozano Álvarez, Miguel Juárez Antonio, Filiberto Juárez Antonio, Daniel Piña, Daniel Celin, Carlos Axel Pérez Cano, José Luis Naranjo Olivares, Everardo Hernández, Ramiro Tena, Alicia Nahmad Vazquez Structural engineering: BRG: Andrew Liew, Tom Van Mele Concrete development: Holcim Mexico: Jose Alfredo Rodriguez, Carlos Eduardo Juarez, Delia Peregrina Rizo Site construction coordination : R-EX: Alicia Nahmad Vazquez Exhibition content, coordination, and curation : Zaha Hadid Exhibitions and Archives: Jillian Nishi, Margaratia Valova, Daria Zolotareva, Paz Bodelon, Elena Castaldi, Manon Janssens, Woody Yao; ZHCODE: Leo Bieling, Federico Borello, Filippo Nassetti, Marko Margeta, Henry David Louth, Shajay Bhooshan ; BRG: Mariana Popescu, Matthias Rippmann, Noelle Paulson, Philippe Block Sponsors : COMEX ; NCCR Digital Fabrication ; ETH Zurich ; Zaha Hadid Architects ; Steiger Participations SA; Holcim Mexico; Imerys Aluminates ; Boston Consulting Group Special thanks: Grupo Altiva; UNAM Arquitectura