Architects:gad

Area :2113 m²

Year :2021

Photographs :YAOLI STUDIO

Interior Design :Interior Architecture Studio

Landscape Design :Guangzhou Guanji Landscape Co. Ltd.

Project Director : Wei Zhang

Project Creator : Kesuo Wu

Architecture Design Team : Yiran Wang, Xiaoyu Sun, Chenglong Ma, Hengyi Cai, Fangyuan Yang, Yuxin An

Structure Design : Dianyu Sun

Water Supply And Drainage Design : Lian Zhang, Qi Huang

Hvac Design : Fangfang Li

Electrical Design : Guoping Chen

Owner : SUNAC China Holdings (Southeast Region) Group

Construction Drawing Design : gad

Curtain Wall Design : CLASSICAL DECORATION

Floodlight Design : BPI

City : Shaoxing

Country : China

Shaoxing rice wine has a long history and its culture is deeply rooted in this soil. Dongpu Town, where the project is located, has been the center of the Shaoxing wine industry since ancient times, and is known as "Shaoxing old wine comes from Dongpu and you can smell the aroma of wine ten miles away from Dongpu ". The original site was a workshop for producing rice wine, now its red brick chimney is preserved. In the early stage of the project, it will be used as Shaoxing Yellow Rice Wine Exhibition and Experience Hall, including yellow rice wine cultural experience exhibition, bookstore, flower shop, and other functions. Later, it will be converted into a waterfront commercial building containing three restaurants and a bookstore.

The site is surrounded by a dense water network. In ancient times, it was the waterway of Shaoxing Grain transport, facing the Dashu River in the east, with good landscape conditions. The design makes full use of this advantage, the three-story building volume is stacked and retreated back from south to north, forming a number of roof terraces overlooking the Dashu River, creating more possibilities for the later use of the restaurant. On one side of the river, the ground floor exits to form a gray space facing the landscape. As the extension and transition of the interior space, the boundary between interior and exterior is blurred and softened, forming a direct connection with the water surface.

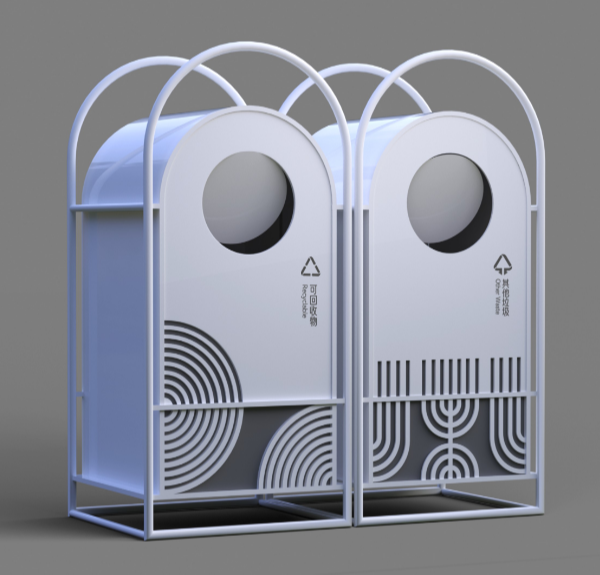

Due to the functional transformation in different periods and the avoidance of large-scale civil construction, the division of architectural space must be flexible. Drawing on the strong functional adaptability of traditional wooden frame architecture and Domino architecture system, the scheme decided to take 4.8mx4.8mx4.8m cubic square as the basic module of the building. This module can simultaneously adapt to the plane and floor height requirements of basic space such as exhibition, shop, restaurant, toilet, elevator room, etc. A smaller span can also achieve higher indoor net height, and meet the requirements of exhibition experience and commercial operation.

This basic modular unit is completely mapped to the form and facade of the building, and the repeated modular units form a unique architectural temperament. Adding another frame to the outer wall of the building allows the interior solid space to retreat and form a deep and layered facade. The awning, which refers to the removable Windows of Jiangnan folk houses, further increases the depth and layers of the facade.

Modular space and modular form are highly unified, bringing the maximum degree of rapid prefabrication and installation, but also fit the actual requirements of rapid construction and cost control. The original plan was to adopt a wooden structure. In consideration of the tight cycle of the project and the fire prevention standards of large-scale wooden structure buildings, as well as the rainy climate in Jiangnan, the poor durability of wooden structure and high maintenance requirements in the later period, the wooden structure form was finally abandoned and the steel frame structure form was adopted which was more fast and controllable.

Through the investigation and comparison of various materials, the facade decoration is made of recycled bamboo as the main material of the exterior wall: The recycled bamboo is made from original bamboo, which has the advantages of convenient materials, simple processing technology, and environmental protection. The bamboo planks are preprocessed into L-shaped members in the factory, which reduces the on-site assembling workload and joint treatment and improves the construction speed and the accuracy of on-site installation. Warm wood materials and small-scale unit space together create a humble, amiable, and vibrant waterfront open space.

The project is an experiment in modular design and construction by the design team. It is associated with traditional Chinese construction methods, and responds to complex functional construction demands with a unified modular design language, responds to the site and history, infuses the vitality of the Times into the thousand-year-old ancient town, and inherits the yellow rice wine culture in a dynamic way.

▼项目更多图片

{{item.text_origin}}