仿生木质展亭 | 数字化创新与高效生态设计

BUGA木质展亭向我们展示了非线性数字化下的木结构。其片段式的木质外壳的设计和建造基于海胆骨架的生物学原理,由斯图加特大学(University of Stuttgart)的计算机设计与建筑研究所(Institute for Computational Design and Construction, ICD)和建筑结构与结构设计研究所(Institute for Building Structures and Structural Design,ITKE)共同研发,前后共耗时将近10年。

The BUGA Wood Pavilion celebrates a new approach to digital timber construction. Its segmented wood shell is based on biological principles found in the plate skeleton of sea urchins, which have been studied by the Institute for Computational Design and Construction (ICD) and the Institute for Building Structures and Structural Design (ITKE) at the University of Stuttgart for almost a decade.

▼从Floßhafen看展亭南侧外观远景,south view of the wood pavilion seen across Floßhafen ©ICD/ITKE University of Stuttgart

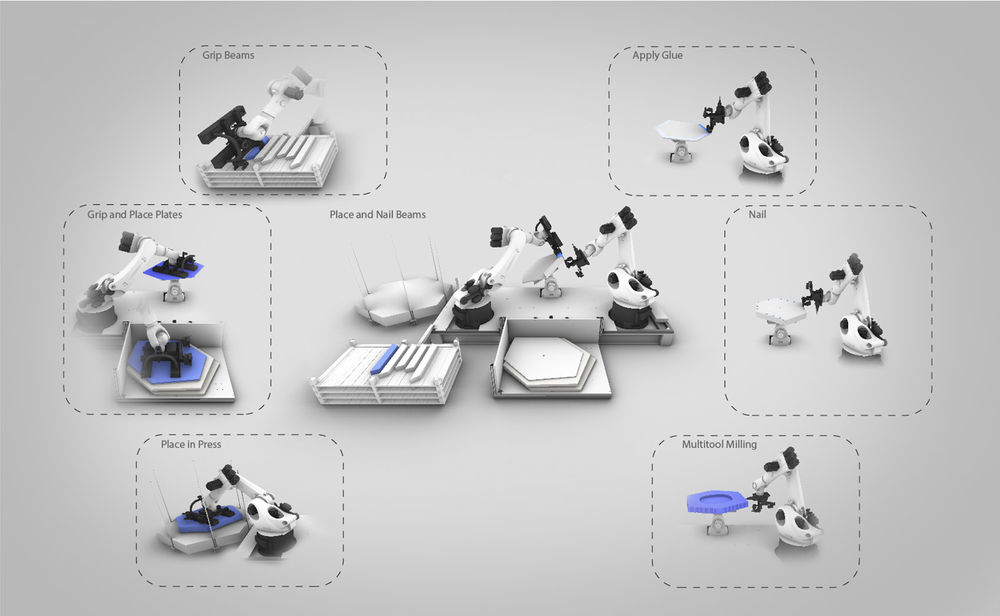

作为该项目的一部分,设计者开发了一个自动制造平台,用于木质展馆的376个定制的空心木片的自动装配和铣削。这种制造工艺能够确保所有的构件都能够以亚毫米的精度组合在一起,就像是一个大型的三维拼图。这个令人惊叹的木质屋顶的跨度高达30米,横跨了BUGA的一个主要活动和音乐会场空间,不仅最大限度地减少了材料使用量,还创造出一个独特的建筑空间。

As part of the project, a robotic manufacturing platform was developed for the automated assembly and milling of the pavilion’s 376 bespoke hollow wood segments. This fabrication process ensures that all segments fit together with sub-millimetre precision like a big, three-dimensional puzzle. The stunning wooden roof spans 30 meters over one of BUGA’s main event and concert venues, using a minimum amount of material while also generating a unique architectural space.

▼从Floßhafen看展亭南侧外观远景,展亭建立在仿生学原理的基础上,south view of the pavilion seen across Floßhafen, the pavilion builds on the biomimetic principle ©ICD/ITKE University of Stuttgart

▼从Karlssee看展亭西侧外观,由376个定制的空心木片的自动装配和铣削而成,west view of the pavilion seen across Karlssee, the pavilion consists of the automated assembly and milling of 376 bespoke hollow wood segments ©ICD/ITKE University of Stuttgart

BUGA木质展亭:一种新颖的结构和建筑空间 BUGA Wood Pavilion: A novel structure and architectural space

预制木质外壳的装配过程由两组工匠在10个工作日内完成,这个过程通常不需要大量的脚手架或是模架样板。在通过可拆卸螺栓连接完所有的构件之后,再在这个建筑结构上铺设一层EPDM箔片作为防水层。未经处理的落叶松木材面板则被作为展亭的外部饰面。所有的建筑元素和构件都是可拆卸且重复使用的。

The prefabricated shell segments were assembled in only 10 working days by a team of two craftsmen, without the usually required extensive scaffolding or formwork. After connecting all segments with removable bolts, a layer of EPDM foil was rolled over the pavilion in 8 strips to provide waterproofing. Untreated larch facade plates provide the external cladding of the pavilion. All building elements are designed for disassembly and reuse on a different site.

▼从BUGA夏季岛屿看展亭西侧外观,采用未经处理的落叶松木材面板作为展亭的外部饰面,west view of the pavilion on the BUGA Summer Island with with untreated larch facade plates as the external cladding of the pavilion ©ICD/ITKE University of Stuttgart

▼从BUGA夏季岛屿看展亭东南侧外观,south-east view of the pavilion on the BUGA Summer Island ©ICD/ITKE University of Stuttgart

▼从BUGA夏季岛屿看展亭南侧外观,south view of the pavilion on the BUGA Summer Island ©ICD/ITKE University of Stuttgart

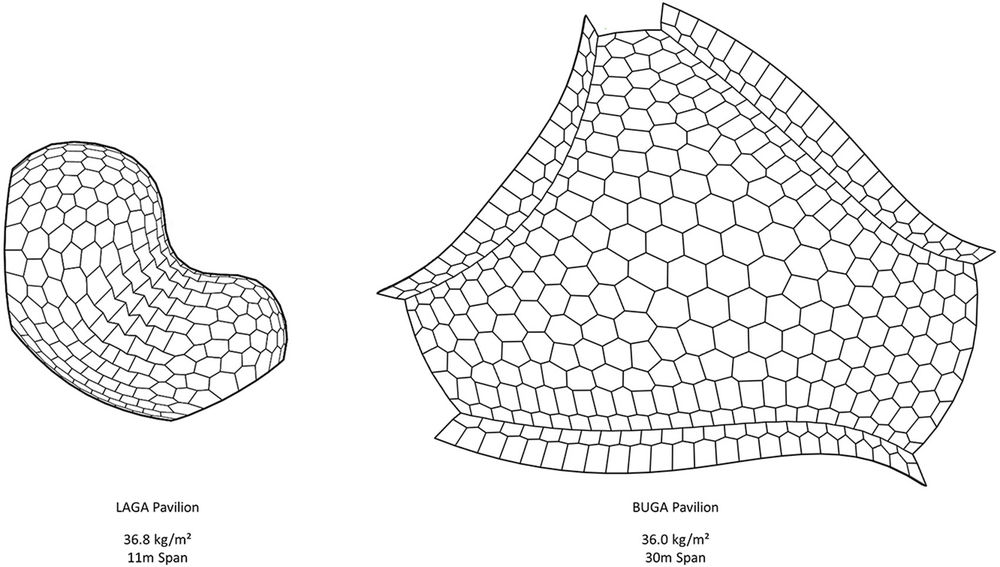

该展亭的承重木质壳体实现了30米的无柱跨度,但其自重仅有38kg/m²。与LAGA展厅相比,本项目在跨度增加了三倍、尺寸增加了五倍的情况下减轻了结构自重。从传统的木工到高科技的自动制造方法,这个由大师级别的工艺、数字化创新设计和多学科科学研究领域共同打造而成的BUGA木质展亭向人们展示了木结构建筑在高效性、经济性、生态型和表现性等方面的可能性。

The pavilion’s loadbearing wood shell achieves a column-free span of 30 meters, but weighs only 38kg/m². This is less than the LAGA exhibition hall benchmark, despite a threefold increase in span and a fivefold increase in size. Drawing a line from traditional carpentry to high-tech robotic fabrication methods, the BUGA Wood Pavilion showcases the possibilities for efficient, economical, ecological and expressive wood architecture that arises at the intersection of master craft, digital innovation and scientific research.

▼展厅西南侧外观,承重木质壳体实现了30米的无柱跨度,south-west view of BUGA Wood Pavilion with its load-bearing wood shell achieving a column-free span of 30 meters ©ICD/ITKE University of Stuttgart

▼展厅南侧外观,south view of BUGA Wood Pavilion ©ICD/ITKE University of Stuttgart

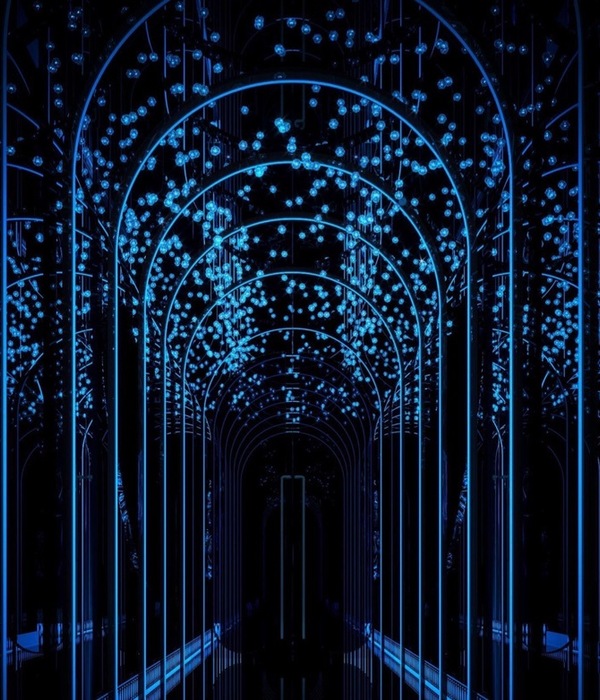

BUGA木质展亭位于BUGA夏季岛屿波浪式景观带中央的十字路口处,将于2019年4月17日在巴登-符腾堡州(State of Baden-Wuerttemberg)的州长的见证下正式对外开放。三个动态的拱门在主要的人流方向形成引人入胜的开口,引导着游客进入展亭的内部空间。这个木质外壳创造出一个平滑弯曲的内部空间,具有非常好的声学效果,同时营造出独特的建筑氛围,人们可以在此举办音乐会和各种公共活动。夜间的时候尤其如此,当壳体内部开口中嵌入的数千盏LED灯被点亮的时候,这个展亭便被笼罩在一种微妙、温暖且温馨的光环境中。此外,对数字化的木建筑系统及其结构的研究将在斯图加特大学新建的“建筑的一体化计算设计和施工”的精英集群片区内进一步展开。

The BUGA Wood Pavilion is located at a central crossroad within the wavy landscape of the BUGA summer island. It will be opened on 17th of April 2019 by the Minister President of the State of Baden-Wuerttemberg. Three dynamic arches form inviting openings in the main directions and guide visitors into the pavilion’s interior. Hosting concerts and public events, the shell creates a smoothly-curved space that provides very good acoustics and generates a unique architectural atmosphere. This is especially true at night, when thousands of LED lights embedded in the shells inner openings light up and bathe the pavilion’s interior in subtle, warm and welcoming light. The research on digital wood building systems and structures will be further pursued in the context of the new Cluster of Excellence “Integrative Computational Design and Construction for Architecture” at the University of Stuttgart.

▼展厅西南侧外观,三个动态的拱门在主要的人流方向形成引人入胜的开口,south-west view of BUGA Wood Pavilion, three dynamic arches form inviting openings in the main directions ©ICD/ITKE University of Stuttgart

仿生的轻质结构:片段式的木质外壳 Biomimetic Lightweight Construction: Segmented Wood Shells

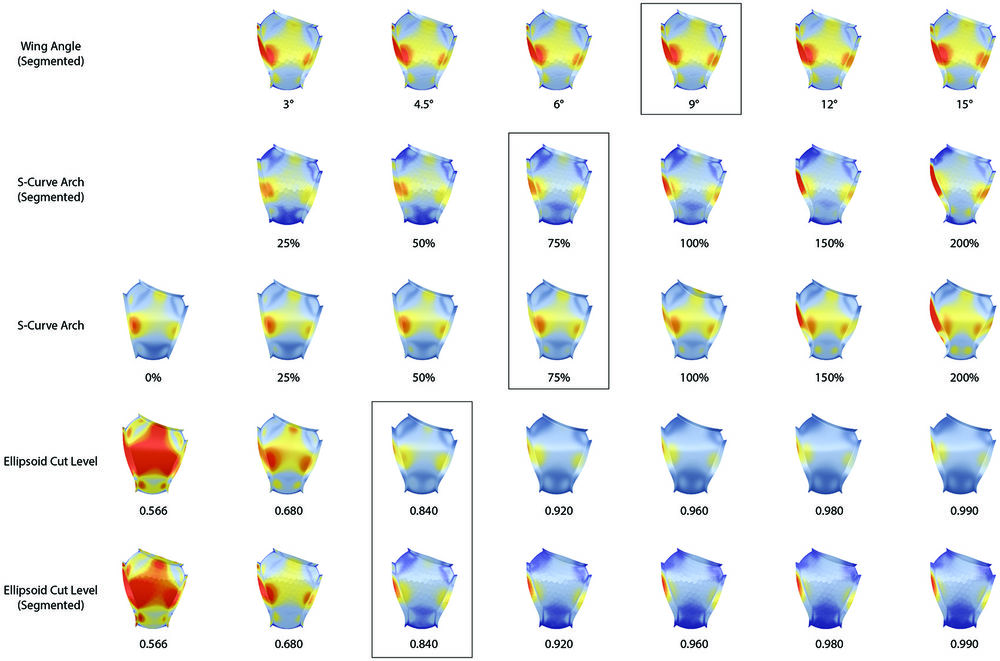

BUGA木质展馆位于德国西南部的海尔布隆(Heilbronn),位于2019年联邦园林展(Bundesgartenschau)场地的中央,以其独特的建筑外形吸引着游客的目光。展馆的设计基于海胆骨架的形态学原理。继完成了位于Schwaebisch Gmuend的前导性项目LAGA展厅后,该项目团队希望能够在本项目中将仿生片段式木质外壳的建筑节点和结构性能提高到一个新的水平层面上:通过使用与LAGA展厅项目中每平方米相同数量的木材,是否有可能建造一个跨度是LAGA展厅的三倍的外壳?同时,这种结构是否可以完全重复使用,从而在不损害其性能的前提下,在BUGA活动之后将其放置在不同的基地上?

The BUGA Wood pavilion provides an architectural attraction at the central summer island of the Bundesgartenschau 2019 in Heilbronn. The design of the pavilion is based on morphological principles of the plate skeleton of sea urchins. Following the precursor research building of the same project team, the LAGA Exhibition Hall in Schwaebisch Gmuend, the research goal of the BUGA Wood Pavilion is pushing the architectural articulation and structural performance of biomimetic segmented wood shells onto a new level: With the same small amount of wood per square meter as in the LAGA project, is it possible to build a shell that reaches triple the span? And can this structure remain fully reusable, so that it can be deployed on a different site after the BUGA without any loss of performance?

▼展厅东北侧外观,设计基于海胆骨架的形态学原理,north-east view of BUGA Wood Pavilion, the design of the pavilion is based on morphological principles of the plate skeleton of sea urchins ©ICD/ITKE University of Stuttgart

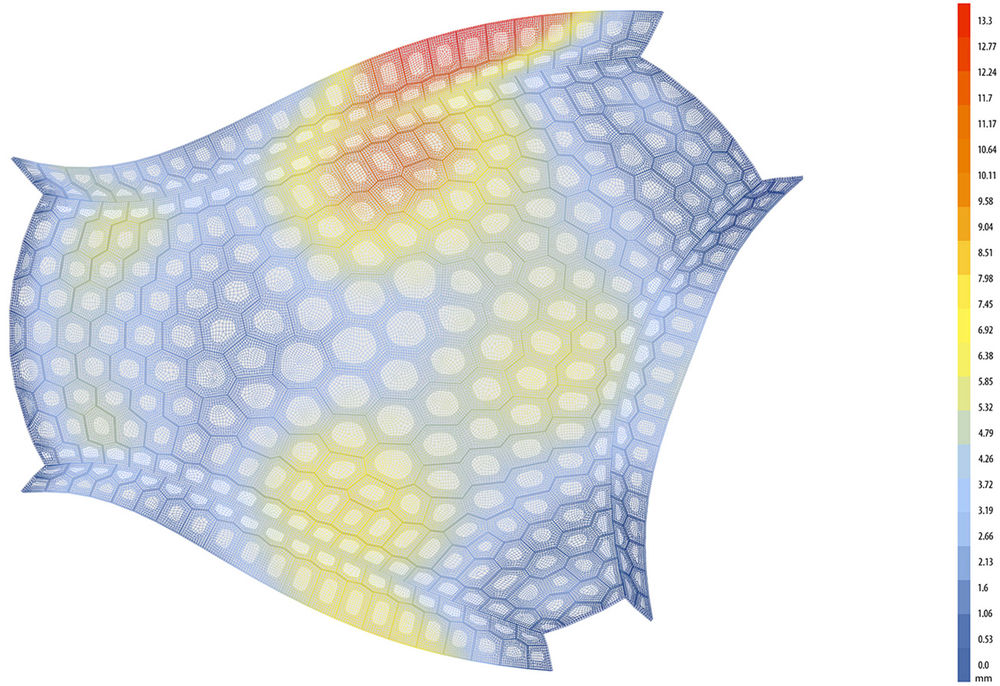

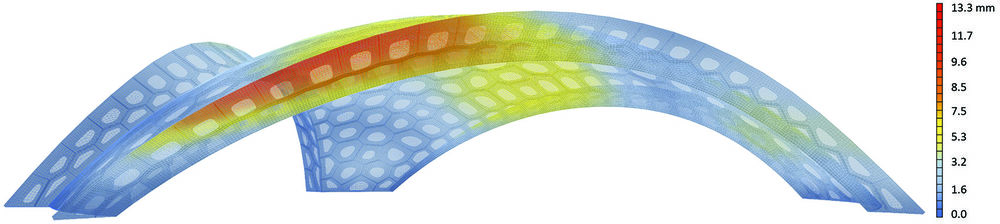

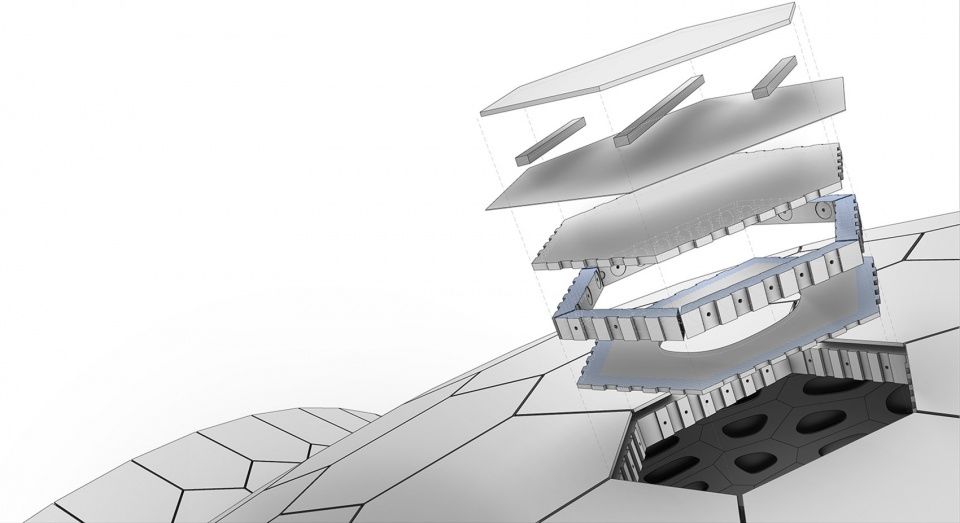

为了实现这一目标,展亭建立在仿生学原理的基础上,通过使用“较少的材料”,在整体外壳和各个独立木片结构的层面上,来创造“较多的形式”。为了最大限度地减少材料消耗量和建筑结构的自重,每个木片均由两块薄板组成,这些薄板在建筑结构的顶部和底部各铺设了一个圈梁,形成了一个多边形形状的大型空心木盒结构。展亭的底部有一个大型的开口,构成了一个独特的建筑特征,同时能够让人们看到在组装过程中被隐藏起来的连接节点。轻质的建筑元素通过指形接头连接起来,同时遵循海胆骨架边缘结构的形态学原理。在组装的过程中,这个壳体结构通过其富有表现力的双曲面几何形状,成为了一个起着形态作用的结构体。

To achieve this goal, the pavilion builds on the biomimetic principle of using “less material” by having “more form”, both on the level of the overall shell and its individual segments. In order to minimize material consumption and weight, each wood segment is built up from two thin plates that plank a ring of edge-beams on top and bottom, forming large scale hollow wooden cases with polygonal forms. The bottom plate includes a large opening, which constitutes a distinctive architectural feature and provides access to the hidden connections during assembly. The lightweight building elements are connected by finger joints, which follow the morphological principles of anatomic features found on the edge of sea urchins’ plates. In the assembled state, the shell works as a form-active structure through its expressive doubly-curved geometry.

▼展厅北侧外观,展亭建立在仿生学原理的基础上,north view of BUGA Wood Pavilion, the pavilion builds on the biomimetic principle ©ICD/ITKE University of Stuttgart

综合性的(合作)设计:反馈信息驱动的设计、工程建造和制造开发 Integrative (Co)Design: Feedback-driven Design, Engineering and Fabrication Development

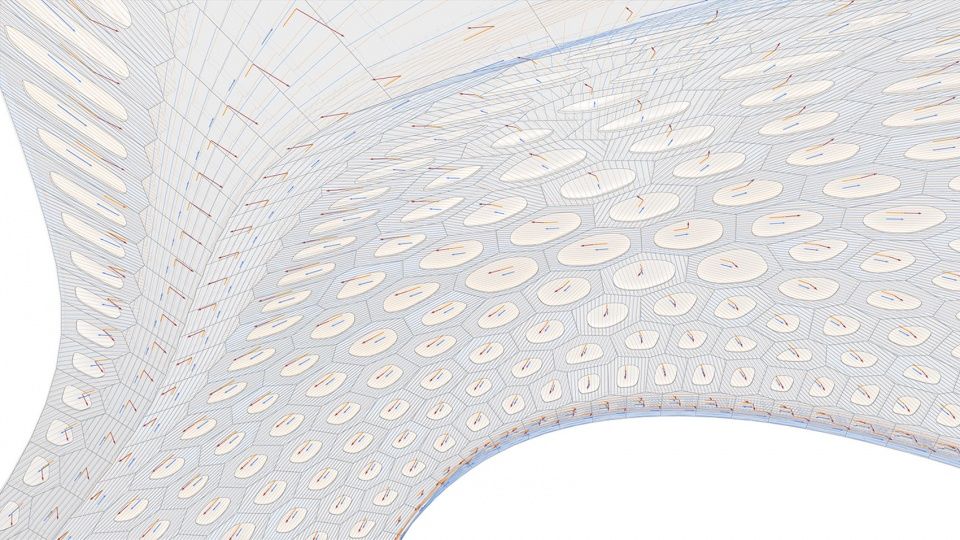

全新的建筑方式需要全新的设计和制造方式。BUGA木质展亭是在合作设计(Co-Design)的范式下进行概念构思的,通过跨学科团队持续性计算的反馈信息,来探索设计、工程建造和制造开发的创新性的可能性。在这个项目中,合作设计的项目团队根据建筑设计的意图和结构的要求生成了展亭各个木壳元素的形状,同时,所有自动制造方面的专业人士都直接参与设计和沟通讨论过程。展亭的各方面设计同时进行,同时实时参考自动制造装置系统的设计反馈信息,值得一提的是,这个自动制造装置系统是为本项目量身定做的。

▼木片单体结构体系爆炸图,explosion diagram of the shells hollow segments and facade layers ©ICD/ITKE University of Stuttgart

New ways of building require new ways of designing and manufacturing. The BUGA Wood pavilion was conceived under the paradigm of Co-Design, where novel possibilities in design, engineering and fabrication are explored through continuous computational feedback within an interdisciplinary team. In this project, the co-design algorithms developed by the project team generate the shape of each element of the pavilion according to architectural design intent and structural requirements, while all robotic fabrication aspects are directly embedded and negotiated. The design of the pavilion happens concurrently and in feedback with the design of the robotic manufacturing set-up, which is a bespoke development for the project.

▼展亭外壳细节,其底部有一个大型的开口,detail view of spine arch of the BUGA Wood Pavilion with a large opening at the bottom plate ©ICD/ITKE University of Stuttgart

▼展亭外壳拱细节,采用片段式的木质外壳,detail view of spine arch of the BUGA Wood Pavilion with segmented wood shells ©ICD/ITKE University of Stuttgart

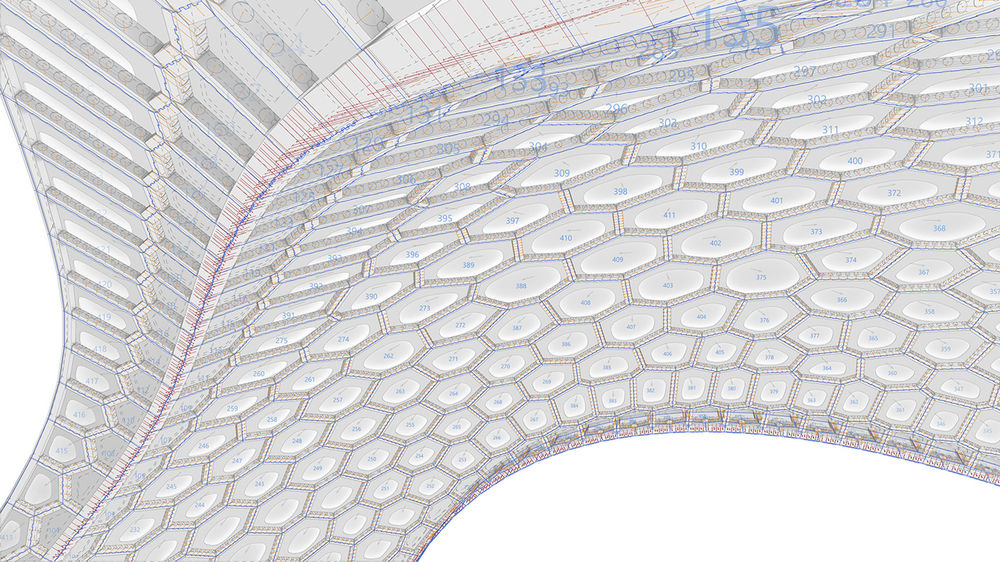

高度整合的设计流程可以处理376个各不相同的木片的设计和制造过程以及17,000个不尽相同的指形接头,以响应多方面的设计标准,从整体结构的大规模尺度到亚毫米精度的细节都可以照顾周全。在不损失精度的前提下,这种多尺度的设计方法能够同时解决建筑和结构两方面的问题。尽管该项目具有首创性,尽管从接到项目委托到最终的联邦园林展开幕仅有13个月的时间,本项目的综合计算过程仍然极为精细,考虑到了所有微小的细节和建筑元素。

▼交互式设计模型,木板不同纹理方向分析,interative planning model (grain), computational model showing the plates’ design of different grain directions ©ICD/ITKE University of Stuttgart

The highly integrative process enables the design and engineering of 376 unique plate segments with 17 000 different finger joints in response to multifaceted design criteria, from the scale of the overall structure down to sub-millimetre details. Without any loss of precision, this multi-scale approach allows addressing architectural and structural considerations concurrently. Despite the pioneering character of the project, and despite an incredible short development time of only 13 months from commission to the opening, the integrative computational process allows for the careful design of each building element in minute detail.

▼展亭内部的灵活性活动空间,interior and flexible event space of the BUGA Wood Pavilion ©ICD/ITKE University of Stuttgart

▼展亭内部细节,detail interior view of spine arch of the BUGA Wood Pavilion ©ICD/ITKE University of Stuttgart

自动预制:将自动装配与高精度加工相结合 Robotic Prefabrication: Combining Automated Assembly with High-Precision Machining

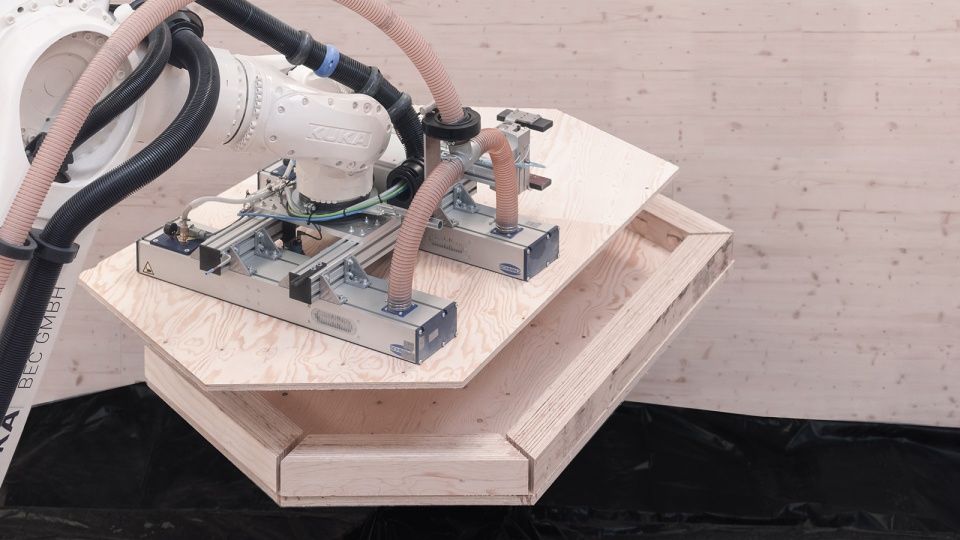

与项目团队在LAGA展厅中使用的实木板相比,本项目所采用的中空木质结构显著地减轻了建筑结构的自重,减少了耗材量,但与此同时,建筑部件的数量增加了八倍,直接导致了更为复杂的制造过程。因此,在本项目中,需要将争取更高资源效率的目标与壳体构件的自动化生产制造联合起来。为此,斯图加特大学建筑结构与结构设计研究所和BEC股份有限公司合作开发了一种新型可移动的14轴木材自动制造平台,生产制造过程则在其工业合作伙伴MuellerBlaustein Holzbauwerke股份有限公司内进行。该平台包括两个高负荷的工业机械系统,这两个机械系统被安装在20英尺高的标准集装箱底座上。工业机械系统的灵活性使得展亭的所有预制过程都能够聚集在一个紧凑的制造单元中完成。

Compared to a solid wood plate, as for example used in the team’s LAGA Exhibition Hall, the hollow building segments significantly reduce weight and material, but they increase the number of building parts eightfold and lead to more complex manufacturing. Thus, striving for higher resource efficiency needs to go hand in hand with automated robotic manufacturing of the shell segments. For this, a novel, transportable, 14-axes robotic timber-manufacturing platform was developed by ICD University of Stuttgart and BEC GmbH, and located at the industrial partner MuellerBlaustein Holzbauwerke GmbH for production. The platform includes two high-payload industrial robots mounted on a 20-foot standard container base. The flexibility of industrial robots allows the integration of all pre-fabrication steps of the pavilion’s segments within one compact manufacturing unit.

▼施工过程,放置顶板,木片单体采用中空的形式,the construction process, the placement of Top Plate, the wood segments are hollow ©ICD/ITKE University of Stuttgart

▼构件预制装配过程,the assembly of spine arches of the BUGA Wood Pavilion ©ICD/ITKE University of Stuttgart

在生产过程中,每个定制的木质壳体构件都是机械组装的。这就需要预先设置好木板和梁、这二者之间的榉木钉临时固定节点,以及梁板之间结构胶接处的受控性应用程序。在第二步中,复杂的指形接头和开口被加工成300微米精度的区段。从梁板的组装,到多工具加工和感官过程,再到图像的质量控制,一切都在完全自动化的工作流程中进行,这个工作流程由200万个自定义的机械代码进行控制,而这些代码则是从计算设计框架中直接导出的。平均而言,每个木片的装配时间为8分钟,高精度的铣削过程则需要额外的20-40分钟。

During production, each bespoke shell segment is robotically assembled. This entails the placement of preformatted timber plates and beams, their temporary fixation with beech nails, and the controlled application for the structural glue joint between plate and beam. In a second step, the intricate finger-joints and openings are machined into the segments with 300μm accuracy. From the assembly of beams and plates, to multi-tool machining and sensorial process- and image based quality control – everything happens in a fully automated workflow, controlled by 2 million custom lines of robotic code that were directly exported from the computational design framework. On average, the assembly time per segment is 8 minutes, with the high precision-milling taking another 20-40 minutes.

▼实地装配过程,the assembly on site ©ICD/ITKE University of Stuttgart

▼展厅夜景,night view of the pavilion ©ROLAND HALBE

▼展厅内部夜景,interior night view of the pavilion ©ROLAND HALBE

▼展亭俯视图,top view of pavilion ©ICD/ITKE University of Stuttgart

▼剖面图,section through pavilion ©ICD/ITKE University of Stuttgart

Project Partners: ICD – Institute for Computational Design and Construction, University of Stuttgart: Prof. Achim Menges, Martin Alvarez, Monika Göbel, Abel Groenewolt, Oliver David Krieg, Ondrej Kyjanek, Hans Jakob Wagner ITKE – Institute of Building Structures and Structural Design, University of Stuttgart: Prof. Jan Knippers, Lotte Aldinger, Simon Bechert, Daniel Sonntag Müllerblaustein Bauwerke GmbH, Blaustein: Reinhold Müller, Daniel Müller, Bernd Schmid BEC GmbH, Reutlingen: Matthias Buck, Zied Bhiri Bundesgartenschau Heilbronn 2019 GmbH: Hanspeter Faas, Oliver Toellner

Project Building Permit Process: Landesstelle für Bautechnik: Dr. Stefan Brendler und Dipl.-Ing. Willy Weidner Proof Engineer: Prof. Dr.-Ing. Hugo Rieger MPA Stuttgart: Dr. Simon Aicher

Project Support: State of Baden-Wuerttemberg, University of Stuttgart, EFRE European Union, GETTYLAB, DFG German Research Foundation, Carlisle Construction Materials GmbH, Puren GmbH, Hera Gmbh co.KG, Beck Fastener Group, J. Schmalz GmbH, Niemes Dosiertechnik GmbH & Co. KG, Jowat Adhesives SE, Raithle Werkzeugtechnik, Leuze electronic GmbH & Co. KG, Metsä Wood Deutschland GmbH