StriatusжҳҜдёҖеә§жӢұеҪўзҡ„ж— й’ўзӯӢз ҢдҪ“дәәиЎҢжЎҘпјҢз”ұ3Dжү“еҚ°зҡ„ж··еҮқеңҹз Ңеқ—жһ„жҲҗпјҢз»„иЈ…иҝҮзЁӢдёӯдёҚйҮҮз”ЁзІҳеҗҲеүӮгҖӮиҝҷеә§16Г—12зұізҡ„дәәиЎҢжЎҘз»“еҗҲдәҶеӨ§еёҲзә§е»әйҖ иҖ…зҡ„дј з»ҹжҠҖжңҜпјҢд»ҘеҸҠе…Ҳиҝӣзҡ„и®Ўз®—жңәи®ҫи®ЎгҖҒе·ҘзЁӢе’ҢжңәеҷЁдәәеҲ¶йҖ жҠҖжңҜгҖӮStriatusзӣ®еүҚжӯЈеңЁеЁҒе°јж–Ҝе»әзӯ‘еҸҢе№ҙеұ•зҡ„Giardini della MarinaressaиҠұеӣӯеұ•еҮәпјҢеұ•жңҹе°ҶжҢҒз»ӯиҮі2021е№ҙ11жңҲгҖӮ

в–јйЎ№зӣ®жҰӮи§ҲпјҢpreviewВ В© naaro

Striatus is an arched, unreinforced masonry footbridge composed of 3D-printed concrete blocks assembled without mortar. Exhibited at the Giardini della Marinaressa during the Venice Architecture Biennale until November 2021, the 16Г—12-metre footbridge is the first of its kind, combining traditional techniques of master builders with advanced computational design, engineering and robotic manufacturing technologies.

в–јStriatusдәәиЎҢжЎҘпјҢStriatusВ footbridgeВ В© naaro

вҖңStriatusвҖқзҡ„еҗҚз§°пјҲж„ҸдёәеёҰжқЎзә№зҡ„пјүеҸҚжҳ дәҶе…¶з»“жһ„е’ҢеҲ¶йҖ иҝҮзЁӢдёҠзҡ„йҖ»иҫ‘гҖӮж··еҮқеңҹжқҗж–ҷиў«жү“еҚ°жҲҗеһӮзӣҙдәҺдё»иҰҒз»“жһ„еҠӣзҡ„еҲҶеұӮпјҢд»ҘеҲӣе»әдёҖз§Қж— йңҖеҠ еӣәзҡ„гҖҒзәҜеҺӢзј©зҡ„вҖңжқЎзҠ¶вҖқз»“жһ„гҖӮ

The name вҖңStriatusвҖқ reflects its structural logic and fabrication process. Concrete is printed in layers orthogonal to the main structural forces to create a вҖңstriatedвҖқ compression-only funicular structure that requires no reinforcement.

в–јеҪўдҪ“з”ҹжҲҗпјҢvolume generationВ В© Zaha Hadid Architects

StriatusжҸҗеҮәдәҶдёҖз§Қж–°зҡ„ж··еҮқеңҹиҜӯиЁҖпјҢе®ғз»“жһ„еҗҲзҗҶгҖҒеҲ¶йҖ ж–№жі•жҳҺзЎ®гҖҒеҜ№з”ҹжҖҒиҙҹиҙЈпјҢ并且иғҪеӨҹеҮӯеҖҹзІҫзЎ®зҡ„и®ҫи®Ўжҳҫи‘—иҠӮзәҰжҲҗжң¬гҖӮStriatusдјҳеҢ–дәҶз ҢдҪ“з»“жһ„гҖҒ3Dж··еҮқеңҹжү“еҚ°пјҲ3DCPпјүе’ҢеҪ“д»Ји®ҫи®Ўд№Ӣй—ҙзӣёдә’е…іиҒ”зҡ„зү№жҖ§пјҢжҸҗеҮәдәҶдёҖз§ҚиғҪеӨҹжӣҝд»Јдј з»ҹж··еҮқеңҹе»әзӯ‘зҡ„еҸҜиЎҢж–№жЎҲгҖӮ

Proposing a new language for concrete that is structurally informed, fabrication aware, ecologically responsible and precisely placed to build more with less, Striatus optimises the interrelated properties of masonry structures, 3D concrete printing (3DCP) and contemporary design; presenting an alternative to traditional concrete construction.

в–јStriatusз”ұ3Dжү“еҚ°зҡ„ж··еҮқеңҹз Ңеқ—жһ„жҲҗпјҢStriatus isВ composed of 3D-printed concrete blocksВ В© naaro

StriatusжҳҜдёҖдёӘж— й’ўзӯӢзҡ„ж··еҮқеңҹз»“жһ„пјҢеҮӯеҖҹеҮ дҪ•еҪўзҠ¶иҺ·еҫ—дәҶејәеәҰгҖӮж··еҮқеңҹеҸҜд»Ҙиў«зңӢеҒҡжҳҜдёҖз§Қдәәе·ҘзҹіжқҗпјҢжӢҘжңүжңҖеҘҪзҡ„еҺӢзј©жҖ§иғҪгҖӮеңЁжӢұеҪўе’ҢжӢұйЎ¶з»“жһ„дёӯпјҢжқҗж–ҷеҸҜд»Ҙиў«зІҫзЎ®ең°ж”ҫзҪ®пјҢд»ҺиҖҢдҪҝеҠӣеңЁзәҜзІ№зҡ„еҺӢзј©дёӯдј йҖ’еҲ°ж”Ҝж’‘зү©дёҠгҖӮиҝҷз§Қжғ…еҶөдёӢпјҢз»“жһ„зҡ„ејәеәҰжҳҜеҖҹеҠ©еҮ дҪ•еҪўзҠ¶иҖҢдә§з”ҹзҡ„пјҢиҖҢдёҚжҳҜеғҸдј з»ҹзҡ„ж··еҮқеңҹжўҒе’Ңж°ҙе№іжҘјжқҝйӮЈж ·д»ҘдҪҺж•Ҳзҡ„ж–№ејҸиҝӣиЎҢжқҗж–ҷе Ҷз§ҜгҖӮиҝҷдёҚд»…жңүеҲ©дәҺжҳҫи‘—еҮҸе°‘иҗҘйҖ з©әй—ҙжүҖйңҖзҡ„жқҗж–ҷж•°йҮҸпјҢеҗҢж—¶иҝҳиғҪеӨҹйј“еҠұдәә们жӣҙеӨҡең°дҪҝз”ЁдҪҺејәеәҰгҖҒдҪҺжұЎжҹ“зҡ„жқҗж–ҷиҝӣиЎҢе»әйҖ гҖӮ

в–јеҠӣеӯҰеҲҶжһҗпјҢanalysis of displacementВ В© Zaha Hadid Architects

Striatus is an unreinforced concrete structure that achieves strength through geometry. Concrete can be considered an artificial stone that performs best in compression. In arched and vaulted structures, material can be placed precisely so that forces can travel to the supports in pure compression. Strength is created through geometry, rather than an inefficient accumulation of materials as in conventional concrete beams and flat floor slabs. This presents opportunities to significantly reduce the amount of material needed to span space as well as the possibility to build with lower-strength, less-polluting alternatives.

в–јз»“жһ„зҡ„ејәеәҰжҳҜеҖҹеҠ©еҮ дҪ•еҪўзҠ¶иҖҢдә§з”ҹпјҢStrength is created through geometryВ В© naaro

в–јжӢұи…№пјҢthe bridgeВ soffitВ В© naaro

в–јз»ҶиҠӮпјҢdetailed viewВ В© naaro

StriatusйҮҮз”ЁеҫӘзҺҜи®ҫи®ЎпјҢд»…еңЁйңҖиҰҒзҡ„ең°ж–№ж”ҫзҪ®жқҗж–ҷпјҢд»ҺиҖҢеӨ§е№…еҮҸе°‘дәҶе…¶еҜ№зҺҜеўғйҖ жҲҗзҡ„еҪұе“ҚгҖӮStriatusйҮҮз”Ёе№ІејҸз»„иЈ…пјҢдёҚдҪҝз”Ёй’ўзӯӢе’ҢзІҳеҗҲеүӮпјҢеҸҜд»ҘеҸҚеӨҚең°иҝӣиЎҢе®үиЈ…гҖҒжӢҶеҚёгҖҒйҮҚз»„жҲ–жӣҙжҚўз”ЁйҖ”пјҢе……еҲҶең°еұ•зӨәдәҶеҸҜжҢҒз»ӯжҖ§зҡ„3RеҺҹеҲҷпјҲReduce, Reuse, RecycleпјүеңЁж··еҮқеңҹз»“жһ„дёӯзҡ„жҲҗеҠҹеә”з”ЁгҖӮ

Circular by design, Striatus places material only where needed, significantly reducing its environmental footprint. Built without reinforcement and using dry assembly without binders, Striatus can beВ installed, dismantled, reassembled and repurposed repeatedly; demonstrating how the three RвҖҷs of sustainability (Reduce, Reuse, Recycle) can be applied to concrete structures.

в–јStriatusйҮҮз”Ёе№ІејҸз»„иЈ…пјҢдёҚдҪҝз”Ёй’ўзӯӢе’ҢзІҳеҗҲеүӮпјҢStriatus is built without reinforcement and using dry assembly without bindersВ В© naaro

е’Ңе…ёеһӢзҡ„жҢӨеҺӢејҸ3Dжү“еҚ°дёҚеҗҢпјҢStriatusйҮҮз”Ёзҡ„жҳҜеҸҢз»„пјҲ2Kпјүж··еҮқеңҹеўЁж°ҙд»ҘеҸҠзӣёй…ҚеҘ—зҡ„жү“еҚ°еӨҙе’ҢжіөйҖҒиЈ…зҪ®пјҢиғҪеӨҹйҖҡиҝҮдёҖдёӘ6иҪҙзҡ„еӨҡж–№дҪҚжңәжў°иҮӮзІҫеҮҶең°жү“еҚ°дёҚеқҮеҢҖеұӮе’Ңйқһе№іиЎҢеұӮгҖӮиҝҷз§Қж–°дёҖд»Ј3Dж··еҮқеңҹжү“еҚ°жҠҖжңҜдёҺжӢұеҪўз ҢдҪ“и®ҫи®Ўзӣёз»“еҗҲпјҢе…¶з”ҹдә§еҮәзҡ„жһ„件еҸҜд»ҘеңЁж— йңҖд»»дҪ•еҠ еӣәжҲ–еҗҺеҠ жӢүеҠӣзҡ„жқЎд»¶дёӢе®һзҺ°жүҝйҮҚгҖӮ

Unlike typical extrusion 3D printing in simple horizontal layers, Striatus uses a two-component (2K) concrete ink with corresponding printing head and pumping arrangement to precisely print non-uniform and non-parallel layers via a 6-axis, multi-DOF robotic arm. This new generation of 3D concrete printing in combination with the arched masonry design allows the resulting components to be used structurally without any reinforcement or post-tensioning.

в–јжү“еҚ°иҝҮзЁӢпјҢprintingВ В© in3d

йў„и®ЎеңЁжңӘжқҘ30е№ҙеҶ…пјҢе…Ёзҗғе°Ҷе»әжҲҗ3000дәҝе№іж–№зұізҡ„ж–°жҘјеұӮпјҢиҖҢжҘјжқҝжң¬иә«зҡ„йҮҚйҮҸе°ҶеҚ жҚ®еӨ§еӨҡж•°й«ҳеұӮе»әзӯ‘пјҲ10еұӮд»ҘдёҠпјүйҮҚйҮҸзҡ„40%д»ҘдёҠгҖӮStriatusе»әйҖ ж–№ејҸзҡ„еј•е…Ҙе°ҶзңҹжӯЈең°йў иҰҶе»әзӯ‘иЎҢдёҡвҖ”вҖ”ж”№еҸҳжҲ‘们и®ҫи®Ўе’Ңе»әйҖ дәәе·ҘзҺҜеўғзҡ„ж–№ејҸпјҢд»ҺиҖҢжӣҙеҘҪең°еә”еҜ№жҲ‘们жүҖеӨ„ж—¶д»Јзҡ„еҶіе®ҡжҖ§жҢ‘жҲҳгҖӮ

With an estimated 300 billion square metres of floor area to be constructed worldwide over the next 30 years, and floors comprising more than 40% of the weight of most high-rise buildings (10+ storeys), introducing the principles demonstrated by Striatus would truly disrupt the construction industry вҖ” transforming how we design and construct our built environment to address the defining challenges of our era.

в–је»әйҖ иҝҮзЁӢпјҢconstruction photoВ В© Alessandro DellвҖҷEndice (top left and bottom);В В© Tom van Mele (top right)

в–јStriatusжҰӮеҝөеӣҫпјҢconcept render В© Zaha Hadid Architects

в–јйЎ№зӣ®ж•ҲжһңеӣҫпјҢrenderingВ В© Zaha Hadid Architects

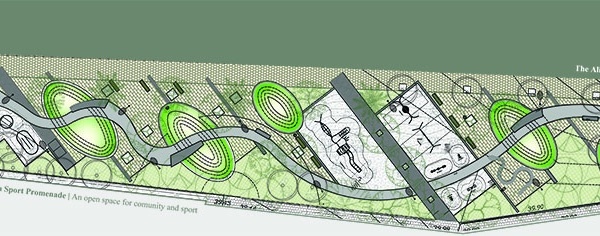

в–је№ійқўеӣҫпјҢplanВ В© Zaha Hadid Architects

в–јз«ӢйқўеӣҫAпјҢelevation AВ В© Zaha Hadid Architects

в–јз«ӢйқўеӣҫBпјҢelevation BВ В© Zaha Hadid Architects

в–јз«ӢйқўеӣҫCпјҢelevation CВ В© Zaha Hadid Architects

в–јеү–йқўеӣҫAпјҢsection AВ В© Zaha Hadid Architects

в–јеү–йқўеӣҫBпјҢsection BВ В© Zaha Hadid Architects

Striatus An arched 3D-concrete-printed masonry bridge A project by the Block Research Group (BRG) at ETH Zurich and Zaha Hadid Architects Computation and Design Group (ZHACODE), in collaboration with incremental3D (in3D), made possible by Holcim

Full credits Design ZHACODE: Jianfei Chu, Vishu Bhooshan, Henry David Louth, Shajay Bhooshan, Patrik Schumacher ETH BRG: Tom Van Mele, Alessandro DellвҖҷEndice, Philippe Block Structural engineering ETH BRG: Tom Van Mele, Alessandro DellвҖҷEndice, Sam Bouten, Philippe Block Fabrication design ETH BRG: Shajay Bhooshan, Alessandro DellвҖҷEndice, Sam Bouten, Chaoyu Du, Tom Van Mele ZHACODE: Vishu Bhooshan, Philip Singer, Tommaso Casucci 3D concrete printing In3D: Johannes Megens, Georg Grasser, Sandro Sanin, Nikolas Janitsch, Janos Mohacsi Concrete material development Holcim: Christian Blachier, Marjorie Chantin-Coquard, Helene Lombois-Burger, Francis Steiner LafargeHolcim Spain: Benito Carrion, Jose Manuel Arnau Assembly & Construction BГјrgin Creations: Theo BГјrgin, Semir MГӨchler, Calvin Graf ETH BRG: Alessandro DellвҖҷEndice, Tom Van Mele Logistics ETH BRG: Alessandro DellвҖҷEndice, Tom Van Mele Holcim Switzerland & Italy: Michele Alverdi LafargeHolcim Spain: Ricardo de Pablos, JosГ© Luis Romero Additional partners Ackermann GmbH [CNC timber formwork] L2F Architettura [site measurements] Pletscher [steel supports] ZB Laser [lasercutting neoprene] Documentation ZHACODE: Jianfei Chu, Cesar Fragachan, Vishu Bhooshan, Philip Singer, Edward Meyers, Shajay Bhooshan ETH BRG: Tom Van Mele, Alessandro DellвҖҷEndice, Philippe Block In3D: Alexander Gugitscher, Sandro Sanin, Nikolas Janitsch naaro LBS Fotografia

{{item.text_origin}}