预制乡村别墅 | 绿色环保,适应全家的生活空间

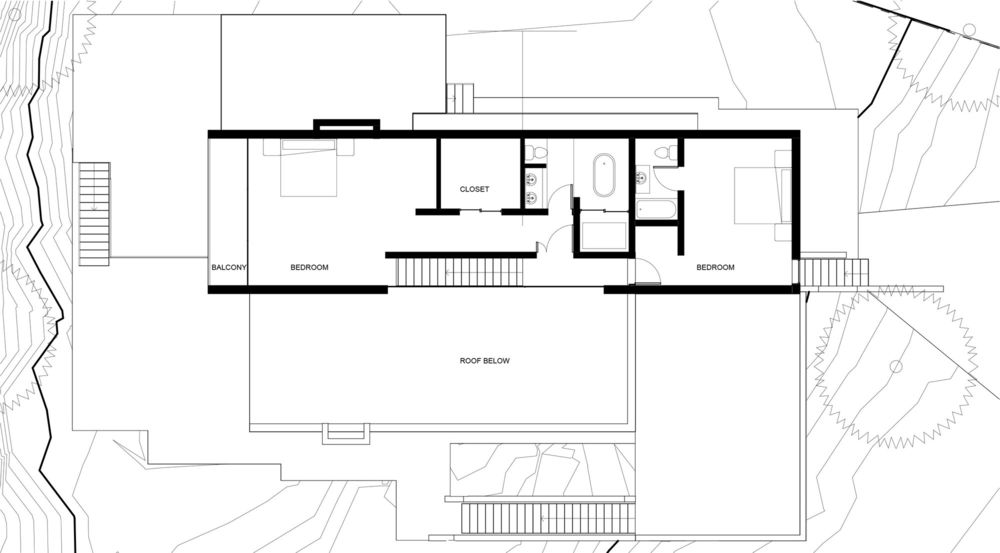

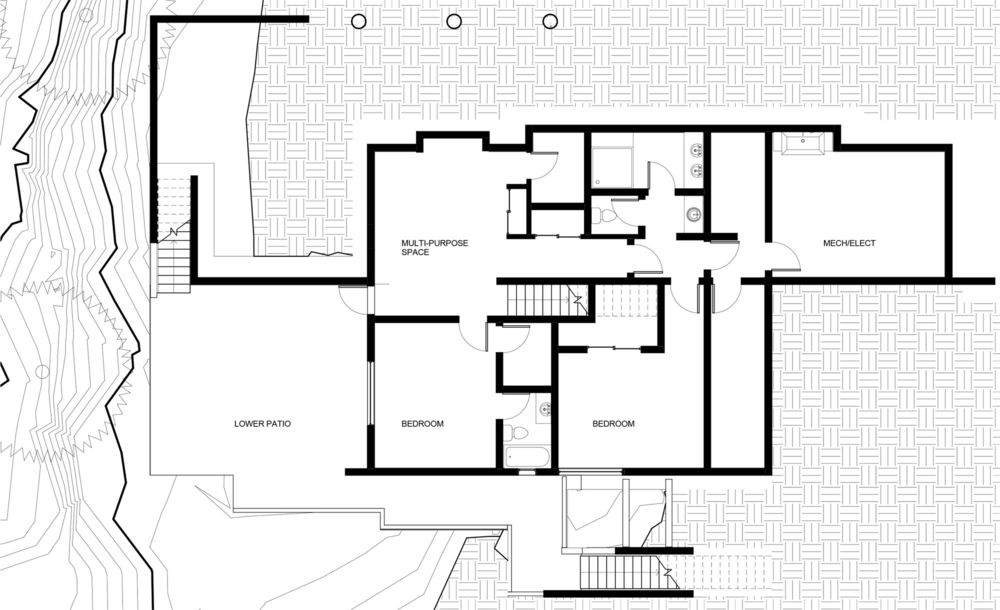

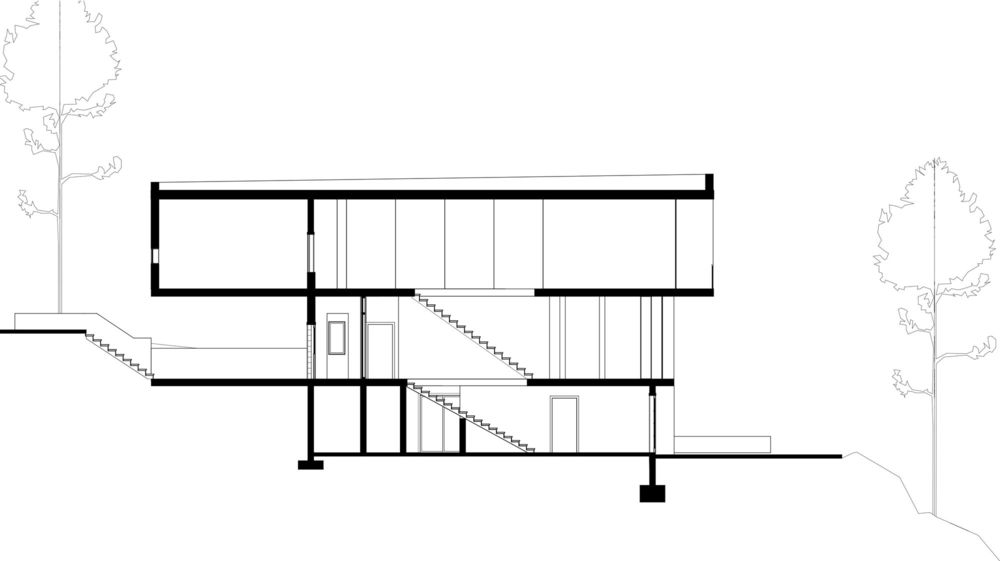

An Unconventional Manufacturing Proces. The house consists of five prefabricated custom modules, each approximately fifty feet long, that are assembled before being delivered to the site. The concept allowed for indoor construction under optimal working conditions. The modular design is unique, created according to precise plans by the architect. The insulation, windows, and flooring were all assembled before shipping. Transporting the giant modules proved to be quite a challenge.

The process included preparation, coordination, and navigating through country roads with ninety degree turns in inclement weather. Construction began in late summer before the demolition of the existing house. This ensured a faster construction so that the family would not lose more than one season enjoying the country.

Low environmental footprint. Conceptualized with the vision of creating an extremely low environmental footprint, the house was built using sustainable and local materials. The large windows capture the beauty of nature in all its glory and flood the inside with light. The direct sunshine helps in reducing both heating and lighting costs. The natural colored outdoor facade blends easily into the woodland decor and the opaque black accents add an artistic flair. The wood used indoors is warm and welcoming. The architect is in the process of applying for a LEED Gold certification for his home.

A place adapted to all. The house interior was designed so that each member of the family has their own personal space. The ground floor’s open concept has a large kitchen and dining area where everyone enjoys cooking and eating delicious meals together, a beautiful, cozy living room space, and a three-season screened-in porch surrounded by a lake and woods. The ground floor also has an atelier for painting and carpentry. The lowered lakeside deck was designed as to not disturb the view of the magnificent scenery.